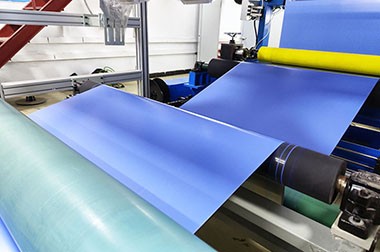

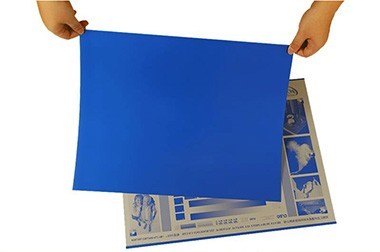

Thermal CTP plate (Single-layer)

Single-layer thermal CTP (Computer-to-Plate) plate is a printing plate used in the offset printing process. CTP technology transfers digital images directly to printing plates, eliminating the need for traditional film methods. This process increases the efficiency and quality of printing operations.

Single-layer thermal CTP plate has excellent performance in printing. Thermal single layer ctp plates require no baking to achieve long print runs. The plate is highly stable and resistant to imaging, development and printing.

Thermal CTP Plate (Single Layer) is a computer-to-plate material based on thermal imaging technology, suitable for offset printing.

The single-layer thermal CTP plate consists of a single positive-working photopolymer coating applied on a chemically grained and anodized aluminum substrate. It offers ultra-high image quality, fine dot reproduction, fast processing, and excellent ink-water balance, supporting 50, 000 to 200, 000 impressions (with post-baking). These plates are compatible with all mainstream thermal CTP plate setters and are ideal for high-speed commercial, newspaper, and packaging printing where quick turnaround and repeatable quality are essential.

Thermal CTP (Computer-to-Plate) technology uses infrared laser diodes to image digital files directly onto the plate. Compared to older CTP technologies, these plates can be handled in daylight, reduce chemical usage, and enhance edge-to-edge image accuracy.

Single-layer thermal CTP plates are designed to be sensitive to thermal imaging equipment. The plate coating absorbs the laser energy, causing a chemical reaction that forms an image on the plate.

- Single-layer thermal CTP plates have a primary coating that is directly imaged by a thermal laser. This simplifies the construction of the plate and improves image quality and consistency.

- Single-layer thermal CTP plates are generally durable and able to withstand long printing periods, making them cost-effective for large printing projects.

- Single-layer thermal plates typically require minimal processing steps, which can simplify workflow and reduce processing time.

Thermal CTP plate (Single-layer) Features

- High quality aluminum material, composite particles and long running length.

- Able to perform bright room operation.

- High resolution and accurate halftone dot reproduction.

- Good development tolerance and easy operation.

Advantages of single-layer thermal CTP plate

- Simplified Workflow: The single-layer design eliminates the need for back coating.

- Accuracy and Precision: The direct imaging process ensures high accuracy and precision in transferring digital images onto the plate.

- Consistency: The single-layer design provides consistent imaging results, reducing variability often seen in multi-layer plates.

- Environmental Benefits: Many single-layer thermal plates are designed to be more environmentally friendly, typically requiring fewer chemicals and generating less waste.

- Ease of Operation: Plates can be handled under bright indoor lighting, making the process more convenient.

- Cost Efficiency: The simplified process reduces chemical usage and workflow steps, lowering operational costs.

- Versatility: Suitable for a wide range of applications including packaging, newspapers, and high-end commercial printing.

Thermal CTP plate (Single-layer ) Technical Data Sheet

| Product type | Single-layer thermal CTP plate |

| Application type | High grade commercial and newspaper printing |

| Plate thickness | 0.15mm, 0.20mm, 0.25mm, 0.30mm, 0.40mm |

| Max width: | 1350mm |

| Spectral sensitivity: | 830nm |

| Exposure energy: | 110~130mj/Cm2 |

| Developing temperature: | 22-28℃ |

| Resolution: | 1~99% at 200lpi |

| Developing time: | 25-35sec |

| Safety-light | 2hours under white light |

| Run length: |

Unbaked: 50 000 - 100 000 impressions ; Baked: more than 100 000impressions. |

| Shelf time: | 18 months |

| Trademark: | Haomei or customized |

| Transportation Package: | Export standard, seaworthy package |

| Specification: |

0.15mm 100PCS/box;0.25mm 50PCS/box;0.30mm 50PCS/box; 0.40mm 30 PCX/box; customized. |

| Origin: | China |

| HS code: | 37013024 |

Structure of Single-Layer Thermal CTP Plate

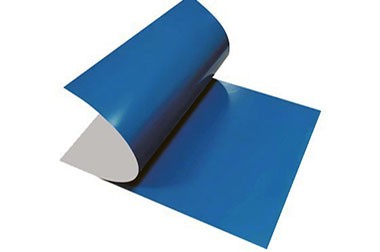

Single-Layer Structure: Composed of an aluminum base and a single thermal-sensitive coating, without multilayer composites.

| Structural Level | Name | Composition and Processing Method | Functions and Features |

| Substrate | Aluminum Base | Aluminum alloy (e.g., 1050/1060), subjected to electrolytic graining and anodizing treatment | Provides good flatness, durability, and chemical stability; forms a hydrophilic surface to enhance water affinity and ink adhesion |

| Photosensitive Layer | Thermal Coating | Contains infrared-absorbing dyes or carbon particles; sensitive to wavelengths of 830nm or 1064nm; uses thermal polymers | Forms oleophilic image areas through laser heating; simplified structure lowers cost; ensures image clarity and resolution |

Aluminum Substrate

The substrate of single-layer thermal plates is high-quality lithographic aluminum plate. It undergoes electrochemical graining and anodizing treatments to form a uniform hydrophilic surface beneath the non-image areas. This surface treatment enhances the water retention in non-printing areas, ensuring accurate ink-water separation and stable printing balance.

Single-layer Photosensitive Polymer Coating

A layer of infrared-sensitive photosensitive polymer is coated onto the aluminum substrate. This layer responds directly to laser exposure without the need for an intermediate mask or back coating, thereby simplifying the production and processing of plates. The single-layer design also minimizes the number of coating components, reducing chemical residues and environmental impact.

The single-layer thermal CTP plate consists of a photosensitive coating applied to a high-quality aluminum base. When exposed to infrared laser (typically 830nm wavelength), the coating undergoes a chemical reaction, forming ink-receptive and non-ink-receptive areas.

Imaging Characteristics of Single-layer Thermal CTP Plates

Spectral Sensitivity and Laser Energy

These plates exhibit peak sensitivity in the 800–830 nm range, which is compatible with standard thermal CTP imagers. Typical exposure energy ranges from 120 to 140 mJ/cm², balancing speed and energy efficiency to achieve high production throughput.

Resolution and Dot Reproduction

Single-layer thermal plates support resolutions up to 200 lpi with a continuous tone dot reproduction range from 1% to 99%. They deliver fine detail and smooth gradients in high-quality commercial and newspaper printing. Even at high screen rulings, precise halftone dot fidelity is maintained, ensuring consistent tonal reproduction across the entire plate.

Plate-making Process of Single-layer Thermal CTP Plates

- Exposure: Direct imaging by infrared laser (e.g., 830nm) using thermal CTP platesetter, no film required.

- Preheating: Some processes require preheating to enhance thermal reaction stability.

- Development: The exposed area is dissolved with alkaline developer, forming a hydrophilic blank area.

- Post-treatment: Cleaning, protective gum coating, with some high-end systems integrating automatic bridge and plate collection units.

Fast Exposure and Development

Due to the high sensitivity of the single-layer coating, exposure times are extremely short, enabling fast plate-making and reducing bottlenecks in the prepress process. After imaging, the plate undergoes a quick chemical rinse step to remove the unexposed polymer and reveal the printing image within seconds.

Post-exposure Baking (Optional)

For extended print runs, baking can be performed after development. Baking enhances the mechanical strength and ink resistance of image areas, increasing the print run from 50, 000 to 100, 000 impressions (unbaked) to 100, 000 to 200, 000 impressions with traditional ink after baking.

Performance and Print Run of Single-layer Thermal CTP Plates

Print Run

- Unbaked print run: 50, 000–100, 000 impressions (with traditional ink).

- Baked print run: 100, 000–200, 000 impressions (with traditional ink), 30, 000–60, 000 impressions with UV ink.

- Durability: Baked plates maintain sharp dots during long print runs and resist scumming, reducing press downtime.

Image Quality and Stability

Single-layer plates exhibit excellent aging stability on press, maintaining dot shape and ink-water balance throughout long print runs without the need for re-baking. Uniform coating consistency also ensures repeatability between plates.

Applications and Compatibility of Single-layer Thermal CTP Plates

Single-layer thermal CTP plate applications

These plates are optimized for high-grade commercial printing, newspaper printing, and packaging jobs where fast turnaround and high fidelity are critical. They perform reliably in both sheet-fed presses and heatset/coldset web printing environments.

Single-layer thermal CTP plates offer many benefits including high image quality, durability and environmental benefits. Their ease of use and consistency make them a popular choice in the printing industry for a wide range of applications.

- Commercial Printing: Used to produce brochures, flyers, catalogs and other marketing materials.

- Newspaper printing: ensuring high-speed, high-quality production of newspapers.

- Packaging: Used for printing on a variety of packaging materials, ensuring durability and high-quality prints.

Single-layer Thermal CTP Platesetter Compatibility

Single-layer thermal plates are compatible with all mainstream 830 nm CTP platesetters on the market, ensuring seamless integration into existing prepress workflows without additional hardware.

Haomei Aluminum thermal CTP plate can meet various requirements of high-end commercial color printing and newspaper printing. It has the advantages of fast plate making speed, good tolerance level, accurate halftone dot reproduction, good ink balance, and long running length.

Single-layer thermal CTP plate enables clear details and high stability. Suitable for medium print runs. This plate does not require preheating. Its fast imaging and development speed maximizes prepress platesetter productivity. This plate is ideal for users who require medium-volume and high-quality commercial printing.

Limitations of Single-layer Thermal CTP

- Exposure Latitude Limitation: Compared to dual-layer plates, single-layer plates may have narrower exposure latitude, requiring stricter control over imaging parameters.

- Post-baking for Long Print Runs: Extending plate durability often depends on baking, which adds extra steps for long print jobs.

Selection and Maintenance of Thermal CTP Plates

| Item | Description |

| Selection of Thermal CTP Plates | Match plate characteristics to printing requirements: |

| Wavelength compatibility: Ensure plate sensitivity matches the CTP device laser wavelength (e.g., 830nm or 1064nm). | |

| Resolution: For fine printing, require 200 lpi or higher. | |

| Print durability: For standard commercial printing, choose under 100, 000 impressions; for long runs, choose 200, 000 impressions or more. | |

| Development requirements: For packaging printing, choose high-durability aluminum-based plates; for short-run fast printing, choose process-free plates to simplify workflow. | |

| Purchasing Considerations | Evaluate the following dimensions comprehensively: |

| Equipment compatibility: Match with the type of platesetter (drum/flatbed) and developer (alkaline/neutral). | |

| Cost-effectiveness: High-durability plates are more expensive but offer long-term economy. | |

| Environmental friendliness: Prefer low-VOC or chemical-free plates. | |

| Environmental adaptability: In humid and hot regions, use moisture-resistant coated plates. | |

| Proper Storage Methods | Ensure storage conditions meet specifications: |

| Environmental parameters: Temperature 20–25°C, humidity 30%–60%, avoid light and UV exposure. | |

| Packaging requirements: Unopened plates should be stored flat in original packaging; opened plates should be sealed to prevent oxidation. | |

| Stacking limitations: Keep away from chemicals, stack height ≤ 1 meter to prevent substrate deformation. | |

| Maintenance Tips | Key operations to extend plate life: |

| Cleaning and protection: Remove ink residues promptly after use; apply gum arabic after development to prevent oxidation. | |

| Equipment calibration: Regularly check CTP laser energy and developer concentration/temperature. | |

| Periodic inspection: During long-term storage, check packaging seal and coating condition; stop using plates if abnormalities are found. |

Comparison Between Thermal CTP and Other Technologies

| Comparison Item | Thermal CTP | Silver Halide CTP | Photopolymer CTP | Process-Free Thermal CTP |

| Imaging Principle | Thermal reaction triggered by infrared laser | Photosensitive emulsion reacts to light, followed by chemical development | Photopolymerization reaction triggered by violet laser, imaged after development | Infrared laser exposure, direct imaging through thermal reaction |

| Operating Environment | Daylight operation | Darkroom required | Safe light environment | Daylight operation |

| Photosensitivity | Medium (50~100μJ/cm²) | Very fast (1~3μJ/cm²) | Medium | Medium |

| Imaging Quality | Sharp dot edges, high stability | Easily affected by development conditions, dots tend to enlarge | Average stability, easily influenced by development fluctuations | Comparable to conventional thermal quality, requires attention to operating environment |

| Dot Reproduction Range | 0.5%~99% | Greatly affected by development | Slightly inferior (limited by development conditions) | Similar to thermal CTP |

| Development Process | Development required (but infrequent) | Development required (more complex developer) | Development required (alkaline developer) | No development needed |

| Environmental Friendliness | Moderate (developer is relatively eco-friendly) | Poor (chemical development with silver content causes pollution) | Fairly good (still needs treatment of development waste) | Optimal (no chemical processing) |

| Print Durability | ≥1 million (after baking) | Medium (more suitable for short runs) | ~250, 000 (unbaked) | ~100, 000 (for sheet-fed printing) |

| Cost Control | Relatively controllable cost, high competition | High cost due to silver content | Moderate cost (plate price relatively stable) | Higher plate price, but no cost for development equipment |

| Application Fields | Commercial printing, long-run printing | Newspaper printing (high speed requirements) | Commercial and packaging printing | Small printing houses, environmentally sensitive companies |

The following PS and CTP plate may interest you

Further reading: ctp thermalctp thermal platepositive thermal ctp platethermal ctpthermal ctp machinethermal ctp platethermal ctp systemsctp platectp machinectp plate making machinecomputer to plate ctpctp plates for offset printingctp printingctp computerctp computer to plate