Processless plate

What are Processless Plates?

Processless plates are an advanced type of printing plate, characterized by the fact that they do not require complex chemical processing steps after imaging. This simplifies the printing process and makes it more environmentally friendly.

Processless plates are designed to improve printing efficiency and quality. Traditional plates typically require multiple post-processing steps, whereas processless plates eliminate these processes.

The core material of processless plates is a special polymer that is sensitive to lasers or light. This material directly generates the image needed for printing from digital files through the action of a laser or light source.

Processless Plate vs Traditional Plates

| Comparison Dimension | Traditional Plates | Processless Plates |

| Processing Steps | Requires chemical development and cleaning | No post-processing required |

| Time and Cost | Complex process, time-consuming and expensive | Simplified process, saving time and cost |

| Environmental Friendliness | Uses chemicals, significant pollution | No chemicals, superior environmental performance |

| Image Quality | Affected by processing steps, may lose details | Direct imaging, high quality and consistency |

| Operational Flexibility | Limited file formats, complex workflow | Flexible file formats, adaptable to digital workflows |

| Plate Lifespan | Prone to chemical corrosion and physical damage | Longer lifespan, strong print durability |

Haomei Aluminum Processless Plate Parameters

| Item | Processless thermal CTP plate |

| Gauge | 0.15mm/0.20mm/0.25mm/0.30mm/0.40mm |

| Spectral Sensitivity | 830 nm |

| Exposure Energy | 130 - 150 mj/cm2 (varies based on platesetter manufacturer and developing condition) |

| Resolution | 1% - 99% @200lpi |

| Run Length | 100, 000 actual run length may vary according to press, ink and paper condition. |

| Developing | not necessary, direct mount on the press |

| Baking | not recommended |

| Safe Light | one hour under fluorescent light without natural light direct irradiation, 4 hours under yellow light |

| Shelf Life | 12 months under recommended storage conditions (10 - 26 degree Celsius, relative humidity: ≤70%, stacking height ≤ 1.5 meter) |

Advantages of Processless Plates

Simplified Process, Reduced Costs

Elimination of Post-Processing Steps: Processless plates do not require intermediate films, chemical development, or washing, significantly simplifying the printing process and reducing the complexity of post-processing steps.

Time Savings: By eliminating several processing steps in traditional plate production, processless plates greatly shorten production cycles, allowing printing tasks to be completed faster.

Cost Reduction: Reduced use of equipment, materials, and chemicals effectively lowers production costs.

Environmental Benefits

- No Chemical Pollution: Processless plates do not use chemical developers or cleaning agents during production, avoiding harmful chemical emissions and reducing environmental impact.

- Reduced Waste: By eliminating the cleaning step, the generation of waste liquids and materials is greatly reduced, helping to lessen the environmental burden.

Image Quality and Flexibility

- High-Resolution Imaging: Processless plates use direct imaging, avoiding subsequent chemical treatments, ensuring sharper and clearer image quality.

- Plate Durability: By omitting chemical and physical processing, processless plates experience less wear and tear, extending their lifespan.

- Workflow Flexibility: Processless plates support direct imaging from digital files and are compatible with various file formats, making them suitable for complex and variable printing tasks.

Stability and Consistency

- Reduced Risk of Errors: Fully automated operations reduce the risk of human error, ensuring higher production stability.

- High Consistency: Due to the direct imaging technology, processless plates ensure consistent results with each print run, guaranteeing high-quality output.

How Do Processless Plates Work?

Exposure Stage

A laser or light source directly interacts with the light-sensitive layer of the processless plate, forming precise image areas based on digital files.

Direct Printing

Once imaging is complete, the plate requires no chemical or physical treatment and can be used directly in printing. The printing press uses the hydrophilic properties of non-image areas and the oleophilic properties of image areas to transfer ink.

No Post-Processing

After exposure, processless plates do not require development, cleaning, or any other treatment steps, significantly simplifying the process.

Popular Processless Plates

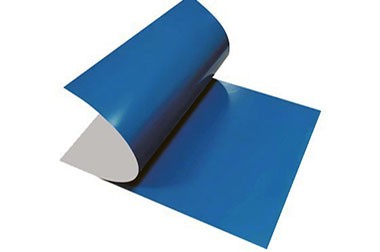

Processless Thermal Plate

A processless thermal plate is a printing plate that can be used directly without a chemical development step. It uses thermal technology, where a thermal laser creates the image on the plate, eliminating the chemical processes required by traditional plates (such as developing and washing).

Processless UV Plate

Processless UV plates can be used directly in printing without chemical treatment. They are typically used in UV printing processes, where exposure and development occur under ultraviolet light, reducing the chemical development steps in traditional printing, thus being environmentally friendly and simplifying the process.

Processless Computer-to-Plate (CTP) Plate

The processless Computer-to-Plate (CTP) plate generates direct images from a computer, without requiring traditional chemical processing steps. It is suitable for both thermal and UV-sensitive plates.

| Feature/Product | Processless Thermal Plate | Processless UV Plate | Processless CTP Plate |

| Technology Principle | Uses thermal technology to directly form the image, eliminating the need for chemical development. | Uses UV-sensitive coating, eliminating the development step. | Directly generates images from a computer, without the need for development. |

| Exposure Method | Thermal laser exposure | UV laser exposure | Direct image generation by laser |

| Development Process | No development, direct printing | No development, direct printing | No development, direct printing |

| Environmental Friendliness | High, reduces the use of chemical developers | High, eliminates the chemical development process | High, eliminates development liquids and cleaning processes |

| Production Efficiency | High, eliminates the development and cleaning processes | High, eliminates traditional development steps | Very high, simplifies the plate-making process, shortening production cycles |

| Applicable Fields | High-efficiency, environmentally-friendly printing needs, especially for commercial and packaging printing | UV printing fields, such as special labels, packaging, and commercial printing | Widely used in commercial printing, packaging printing, book and magazine printing, etc. |

| Image Quality | High, with good image stability | High, suitable for high-precision printing | High, digital control ensures precise and stable image quality |

| Main Advantages | Environmentally friendly, efficient, time-saving | Environmentally friendly, simplifies the plate-making process, improves print quality | Increases production efficiency, reduces costs, stable image quality |

Processless Plate Applications

- Commercial Printing: Such as magazines, posters, brochures, and other high-quality printed materials.

- Packaging Printing: Especially suitable for short-run, quick-turnaround printing needs.

- Environmentally Friendly Printing: The first choice for companies pursuing green printing.

The following PS and CTP plate may interest you

Further reading: computer to plate machinecomputer to platecomputer to plate ctpcomputer to plate printingcomputer to plate systemsctp computerctp computer to platectp computer to plate machine