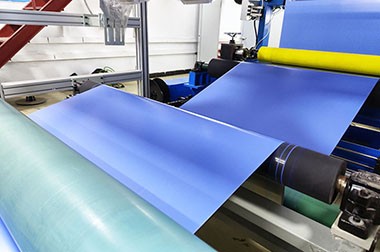

Thermal CTP Plate(Process-less)

Processless Thermal CTP Plate

Thermal CTP (computer-to-plate) plates, especially the process-free versions, simplify the plate-making process for offset printing.

Thermal CTP Plate (Process-less) production is the simplest printing plate production method.

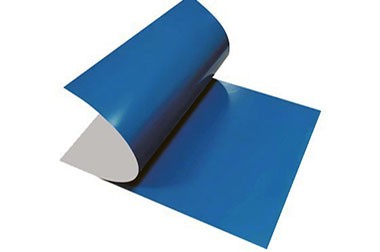

Process-free thermal CTP plates are thermal printing plates that do not require chemical processing or any post-exposure steps after imaging, such as developing, cleaning, or gluing.

After the plate is imaged in the platesetter, it is installed directly on the press, and the removal of the plate coating is cleverly integrated into the press start-up process. Completely eliminating the need for processors, associated chemicals, energy required for processors, water and waste from plate production.

Process-free CTP plates are in contrast to traditional thermal CTP plates that often require chemical processing.

Processless Thermal CTP Plate does not require special chemical treatment after exposure. It can be printed directly on the machine and will not cause any pollution to the environment or printing equipment. It is a green and environmentally friendly printing material and increases work efficiency.

Processless Thermal CTP Plate Features

- 1. High-quality aluminum plate base and photosensitive coating and high print durability.

- 2. Can be operated in a bright room.

- 3. High resolution and accurate dot restoration.

- 4. High development latitude and easy operation.

Thermal CTP Plate (Process-less) working principle

- 1. Imaging: Expose the plate to a thermal laser in a CTP device. A thermal laser selectively changes the coating on the board based on digital image data.

- 2. On-press processing: After imaging, the printing plate is mounted directly onto the printing press. The first few revolutions of the press remove the unexposed coating, effectively developing the plate as part of the printing process itself. This is often called onboard development.

- 3. Printing: The imaged area accepts ink, while the non-imaged area repels ink, allowing the image to be transferred to the substrate (usually paper) like traditional offset printing.

Advantages of processing-free thermal CTP plates

- 1. Simplified workflow: The elimination of chemical processing steps reduces workflow complexity, resulting in faster setup time and lower labor costs.

- 2. Improve efficiency: The use of water, electricity and equipment and the generation of waste are reduced when printing plates, so there is no need to do time-consuming re-measurement, cleaning and maintenance of processors or cleaning equipment, saving pre-press time .

- 3. Environmentally friendly and pollution-free: no chemical developers and flushing solutions are required, and treatment-free printing plates are more environmentally friendly. They reduce hazardous waste and water consumption, making the printing process more environmentally friendly.

- 4. Cost savings: Chemical and water usage is reduced, and processing equipment maintenance requirements are reduced, resulting in significant cost savings over time.

- 5. Improved consistency: Process-free technology improves image consistency and quality because it eliminates variables associated with chemical processing, such as temperature fluctuations and chemical contamination.

- 6. Ease of use: With fewer steps involved in the platemaking process, operators find the technology easier and less error-prone.

Why Choose Process-Free Thermal CTP Plates

- Coating Technology: These plates are coated with a unique heat-sensitive material that reacts to laser exposure to create a long-lasting image on the plate without the need for development.

- Durability: Process-free plates are designed to withstand the rigors of press operation, providing good run lengths and resistance to the abrasion and chemicals used in the printing process.

- Compatibility: They are compatible with most modern thermal CTP systems and can be used in a variety of printing applications from commercial printing to packaging.

Application fields of Processless Thermal CTP Plate

Process-free thermal CTP plates can be used in a variety of printing applications, including:

- commercial printing

- Newspaper printing

- Package

- book printing

- label printing

In summary, heat-free CTP plates represent a significant advancement in printing technology, offering numerous advantages in terms of environmental impact, workflow efficiency and cost savings. They are an excellent choice for modern printing operations looking to increase productivity and sustainability.

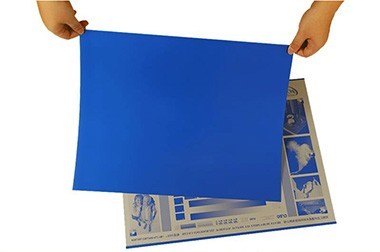

Processless Thermal CTP Plate Technical Data Sheet

| Model No. | Process-less Thermal CTP Plate |

| Usage | High quality commercial and newspaper printing |

| Style | Negative |

| Spectral Sensitivity | 320-450nm |

| Resolution | 2-99% |

| Thickness | 0.15-0.30mm |

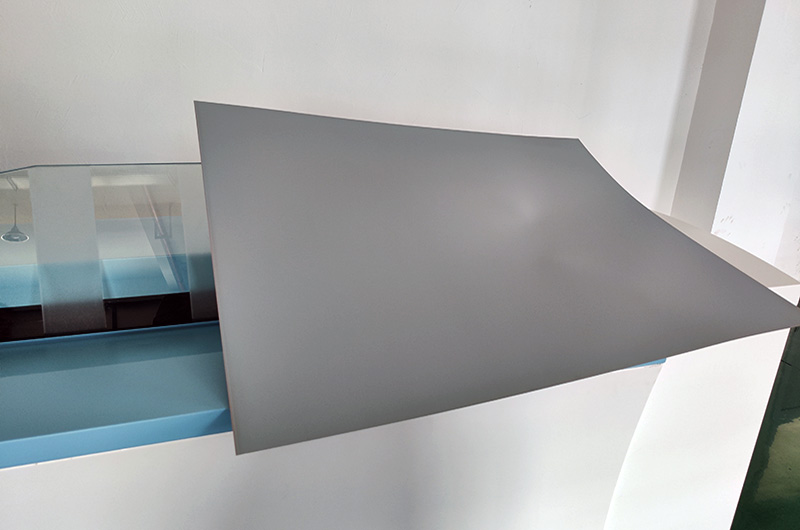

| Colour | Grey |

| Trademark | Haomei or customized |

| Specification | 0.15mm 100PCS/box; 0.30mm 50PCS. |

| HS Code | 3701302 |

| Material | Aluminum |

| Type | CTP Plate |

| Long Impression | 60, 000-100, 000 impressions |

| Sizes | Customized Sizes |

| Developer Temperature | 23+/-2 Degree |

| Laser Energy Required | 80-180mj/Cm2 |

| Transport Package | Export Standard Seaworthy Package |

Haomei Aluminum CTP plates can meet the various needs of high-end commercial color printing and new paper printing. It has the advantages of fast plate making speed, good tolerance, accurate dot reproduction, good ink balance, and long printing run. Processless CTP plates are a new generation of environmentally friendly printing products, suitable for thermal CTP plate making machines. After exposure, it can be printed directly on the machine without any washing steps.

Processless Thermal CTP Plate Precautions

1. Exposure time limit

When using flush-free CTP printing plates, try to avoid prolonged exposure to sunlight.

2. Strict storage requirements

Special wooden boxes are required for storage, and the inside of the wooden box needs to be painted with reflective paint and covered with an embedded lid to avoid light storage.

3. Precautions for loading

During the loading process, try to avoid grabbing directly with your hands, and it is recommended to wear gloves when operating.

4. Precautions for version change

Especially when printing a long version, if dots are lost or the plate needs to be changed during the development process, the flush-free CTP printing plate shows obvious shortcomings. Since the development process relies on fountain solution and the ink roller of the printing machine, changing the plate at this time can easily lead to a large area of dirty plate in the non-inked area (ink on the water roller), which is difficult to deal with and may cause certain losses and inconvenience.

5. Operation precautions

The flush-free CTP printing plate needs to be dampened by a water roller, that is, the water roller is first used to wet the plate for 2 to 3 minutes, and then the ink roller is used to transfer the emulsified adhesive layer to the plate paper to complete the development process. Therefore, printing operators need to change their original operating habits.

The following PS and CTP plate may interest you

Further reading: ctp thermalctp thermal platepositive thermal ctp platethermal ctpthermal ctp machinethermal ctp platethermal ctp systems