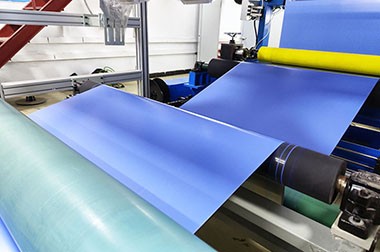

Presensitized offset plate

What is a Presensitized Offset Plate?

A Presensitized Offset Plate is a type of printing plate used in offset printing, typically employed in high-quality, high-volume printing production. It is a plate material that has been pre-coated with a photosensitive layer, making it widely applicable.

Advantages of Presensitized Offset Plates:

- High precision in image reproduction, suitable for printing with fine details.

- Simplified and quick production process, requiring no complex chemical treatments or lengthy preparation.

- Improved production efficiency and cost reduction.

A Presensitized Offset Plate is a printing plate that creates images through a photosensitive reaction, making it widely used in offset printing processes that require high precision and mass production.

What is Meant by Presensitized Plates?

Presensitized plates have been pre-coated with a photosensitive material, so they can be directly exposed. In offset printing, the image is transferred from the aluminum plate, which is treated to have hydrophilic properties (able to absorb water), onto the printing rollers.

Features of Presensitized Offset Plates

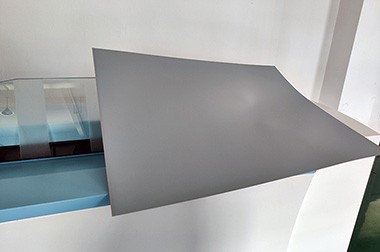

Haomei Aluminum produces plates with excellent surface quality—flawless, without stains or surface defects. The material is of high quality, ensuring the plates remain distortion-free during use and meet the high flatness requirements of offset printing. Electrochemical treatment technology is used to ensure uniform surface roughness.

The heat treatment process gives the plates excellent resistance to thermal softening, effectively preventing deformation under high-temperature conditions.

| Feature | Description |

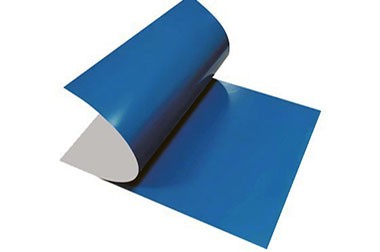

| Photosensitive Coating | The plate surface is coated with a photosensitive resin or other chemicals, which undergo a chemical reaction under UV light. Unexposed areas dissolve, while exposed areas remain insoluble, forming the desired image. |

| Image Reproduction | The image or text from the original (typically a transparent negative) is transferred to the plate surface to create the required image for printing. This process includes exposure and development steps. |

| Convenience | The production process for presensitized offset plates is simple and efficient, allowing for rapid and accurate production of the desired image, especially suited for quick and high-volume printing needs. |

Presensitized Aluminium Offset Plates

Aluminum, as the material for offset printing plates, has many advantages. It is not only lightweight and recyclable but also has a surface roughness that is ideal for offset printing, achieved through electrochemical processing. Therefore, aluminum plates are commonly used as the substrate material for offset printing plates.

The specifications of the presensitized plate substrate

| Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) | Coil ID (mm) |

| 1050, 1052, 1060, 1070 | H16, H18 | 0.13-1.50 | 500-1600 | 500-2000 | 150-510 |

Chemical composition of aluminum material for typical presensitized plate

| Alloy | Tempering | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 1050 | H18 | 0.25 or less | 0.40 or less | 0.05 or less | 0.05 or less | 0.05 or less | 0.05 or less | 0.03 or less | minimum 99.5 |

Mechanical property of aluminum material for typical presensitized plate

| Alloy | Tempering | Tensile strength (N/mm2) | 0.2% yield strength (N/mm2) | Stretch (%) |

| 1050 | H18 | 160 | 150 | 3 |

Presensitized offset plate sizes

| Size | Dimensions (mm) | Dimensions (inches) |

| A3 | 420 x 297 | 16.5 x 11.7 |

| A2 | 594 x 420 | 23.4 x 16.5 |

| B3 | 500 x 355 | 19.7 x 14 |

| B2 | 705 x 510 | 27.8 x 20.1 |

| C | 760 x 570 | 29.9 x 22.4 |

| Full-size | 890 x 640 | 35 x 25.2 |

| Custom sizes | Varies (depending on press) | Varies (depending on press) |

- Custom Sizes: Depending on the printing press, Haomei Aluminum can offer custom sizes.

- Narrow Width: For smaller printing presses, plates with widths such as 18 inches x 24 inches (457 mm x 610 mm) or other non-standard sizes may also be available.

These sizes typically correspond to the format of the printing press, ensuring optimal compatibility and printing efficiency. Different types of printing presses (sheet-fed, web-fed, or digital presses) may require different plate sizes to ensure proper matching.

When ordering presensitized offset plates, it is important to verify the exact size required by the printing press to ensure compatibility.

Popular Offset Printing Plates

| Printing Plate Product | Description |

| 1.14mm Thickness Flexo Photopolymer Plate | A flexible, photopolymer-based plate used in flexographic printing, commonly for packaging and label printing. The 1.14mm thickness is typical for high-quality prints on various substrates. |

| 2.84mm Thickness Flexo Printing Plate | Another type of flexographic plate, but with a thicker 2.84mm profile. It offers durability and is designed for high-volume printing applications, such as corrugated boxes, flexible packaging, and more. |

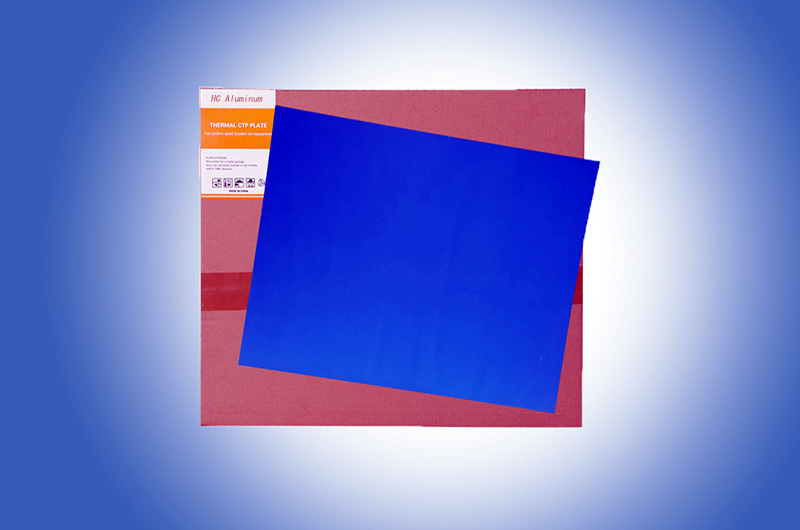

| Aluminum CTP Printing Plate | A computer-to-plate (CTP) printing plate made from aluminum, commonly used in offset printing. This plate is exposed to a laser to transfer digital images directly to the plate, improving precision and efficiency in printing. |

| CTP CTCP Aluminum Printing Plate | A specialized CTP plate that uses the Computer-to-Plate (CTP) system with a conventional thermal chemical process (CTCP). This type of plate is suitable for offset printing with high-quality output. |

| Presensitized Conventional Positive Printing Plate | A presensitized printing plate that is developed through a conventional process. It uses a positive image method, where the image area is exposed to light and developed to create prints in offset printing. |

| Presensitized Offset CTCP Plate | A type of presensitized offset plate that uses the Computer-to-Plate (CTP) system with the CTCP process. It's designed for use in offset printing machines, providing high print quality and efficiency. |

| Printing Thermal CTP Plate | A thermal-based CTP plate used in offset printing, where laser light is used to expose the plate and transfer the image. These plates are known for their high durability and long-lasting performance. |

| PS Plate for 4-Color Offset Printing Machine | A presensitized plate designed for four-color process printing in offset presses. It’s commonly used for printing brochures, magazines, and other full-color print materials. |

| Offset Printing Plate Presensitized PS Plate | A type of presensitized offset plate, where "PS" stands for presensitized. This plate is typically used in conventional offset printing, where the image is chemically developed after exposure to light. |

Working Principle of Presensitized Offset Plate

- Exposure: First, place the original (usually a negative) on the surface of the plate coated with a photosensitive layer, and then expose it to ultraviolet (UV) light. The UV light causes a hardening reaction in certain areas of the photosensitive layer.

- Development: After exposure, the plate is immersed in a developer solution. The areas that were not exposed to UV light will be removed by the developer, leaving behind a raised and recessed structure that forms the desired image for printing.

- Washing and Drying: Finally, the plate is thoroughly cleaned to remove any unreacted photosensitive material and then dried, preparing it for the actual printing process.

Presensitized Offset Plate Printing

Presensitized offset plate printing is widely used, particularly in commercial printing, books, newspapers, magazines, packaging printing, and other fields. They are commonly used on various types of offset printing presses to produce high-quality printed materials.

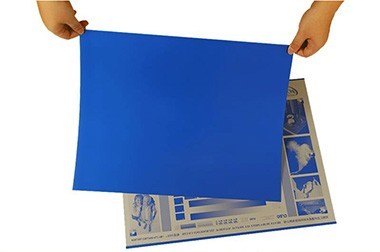

Presensitized Offset Plate Packaging

The plates are placed with the coated sides facing each other, separated by neutral backing paper. The outside is wrapped in black kraft paper with a plastic lining and packed into cardboard boxes. The boxes are placed on wooden pallets reinforced with wooden frames or cardboard and wrapped in kraft paper or plastic film. Finally, the package is secured with plastic tape. Packaging methods can be adjusted based on customer requirements.

The following PS and CTP plate may interest you

Further reading: ctp plates for offset printingctp offset machinectp offset printingctp offset printing platesoffset ctpoffset printing ctp plateoffset printing plate making machine