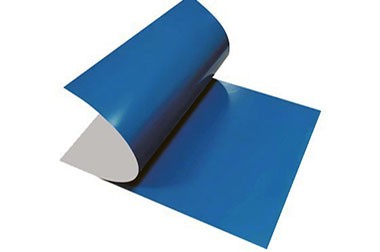

Thermal CTP Plate (Double Layer)

What is thermal CTP plate?

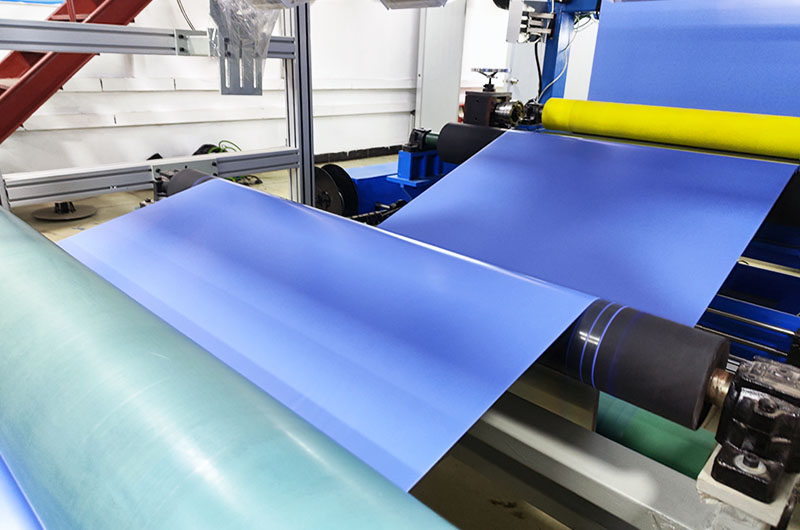

Thermal CTP plates are used in a digital imaging process where a laser is used to expose a digital image directly onto the plate. The plate is then developed and used on a printing press to transfer the image to paper or other substrate.

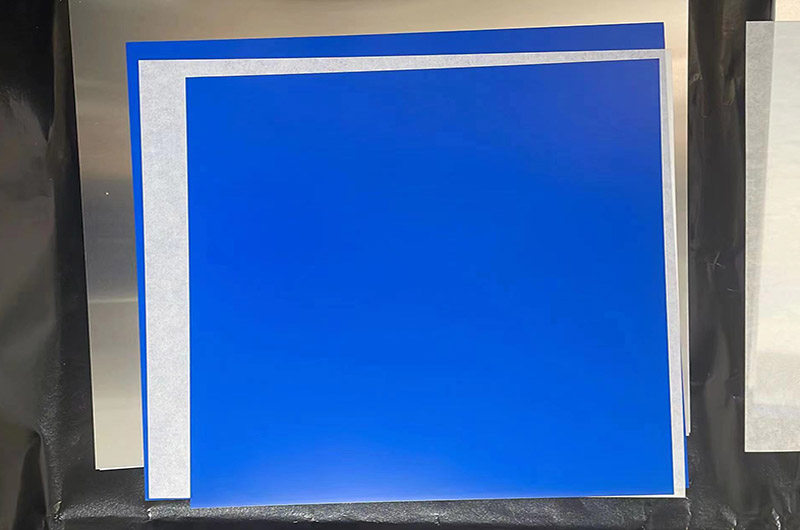

Double Layer Thermal CTP Plate has the characteristics of no need for baking, extremely fast sensitivity, perfect resolution, stable imaging, and ultra-high printing durability. It is a new innovative plate and the first choice for mid-to-high-end printing.

Double-layer thermal CTP plate is a new technology that revolutionizes the printing industry. These plates are made of two layers, a top layer of photosensitive material and a bottom layer of heat-resistant material.

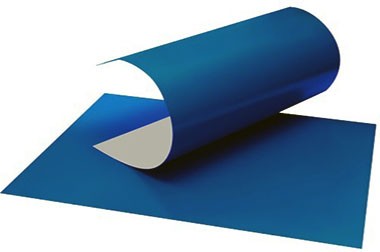

Double Layer Thermal CTP PlateTop layer

- Composition: The top layer is photosensitive material, which is usually composed of heat-sensitive polymer.

- Function: Responds to laser exposure during imaging. Laser energy causes chemical or physical changes in this layer, creating image areas that are receptive to ink.

Double Layer Thermal CTP Plate bottom layer

- Composition: The bottom layer is a heat-resistant material, usually made of aluminum or other durable material, which provides stability and strength.

- Function: This layer supports the top imaging layer and ensures that the plate can withstand the mechanical stresses of the printing process.

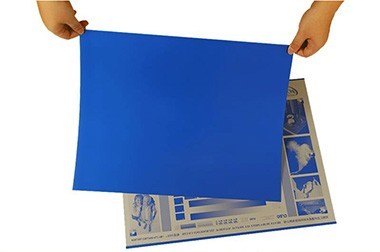

When exposed to light, the photosensitive layer hardens and transfers the image to the underlying layer. This image can then be used to create high-precision and high-definition prints. Double-layer thermal CTP plates are becoming increasingly popular due to their cost-effectiveness and durability compared to traditional printing methods.

The double-coated thermal CTP plate has the characteristics of no need for baking, extremely fast sensitivity, perfect resolution, stable imaging, and ultra-high print durability. It is a new innovative plate and the first choice for mid-to-high-end printing.

Double Layer Thermal CTP Plate Features

- 1. High tolerance, sensitivity, run length

- 2. Excellent image contrast

- 3. Excellent UV ink compatibility

- 4. Consistent quality and stable ink balance

Thermal CTP Plate (Double Layer) Advantages

- 1. Higher resolution and image quality: The top imaging layer is engineered to achieve fine detail and high resolution, which are critical for high-quality print reproduction.

- 2. Durability and longevity: A solid bottom layer enhances the durability of the printing plate, allowing for longer printing runs without degradation.

- 3. Improved chemical resistance: Double-layer printing plates generally exhibit better resistance to the chemicals used in the printing process, resulting in more consistent performance and longer service life.

- 4. Reduce waste and improve cost efficiency: The precise imaging process reduces errors and waste, making the entire printing process more cost-effective.

- 5. Environmental benefits: Double-layer board designs are more environmentally friendly, requiring fewer chemicals and producing less waste.

Double Layer Thermal CTP Plate Technical Data Sheet

| Product type | Double-layer thermal CTP plate |

| Application type | Extremely long run without baking for uv ink printing |

| Plate thickness | 0.15mm, 0.20mm, 0.25mm, 0.30mm, 0.40mm |

| Max width: | 1350mm |

| Spectral sensitivity: | 830nm |

| Exposure energy: | 110~130mj/Cm2 |

| Developing temperature: | 22-28℃ |

| Resolution: | 1~99% at 200lpi |

| Developing time: | 25-35sec |

| Safety-light | 2hours under white light |

| Run length: | Normal ink:100, 000 - 150, 000 impressions . Uv ink:50, 000-100, 000 impressions (actual run length may vary according to printing machine, ink, paper conditions) |

| Shelf time: | 18 months |

| Trademark: | Haomei or customized |

| Transportation Package: | Export standard, seaworthy package |

| Specification: |

0.15mm 100PCS/box;0.25mm 50PCS/box;0.30mm 50PCS/box; 0.40mm 30 PCX/box; customized. |

| Origin: | China |

| HS code: | 37013024 |

Thermal CTP Plate (Double Layer) Applications

Double-layer thermal CTP plates are used in a variety of printing applications, including:

- Commercial Printing: For brochures, magazines, catalogs and other high-quality printed materials.

- Packaging: Durability and high print quality are crucial.

- Newspapers: Where high-speed printing and reliable image reproduction are required.

The dual-layer thermal CTP plate offers significant advantages in image quality, durability and efficiency, making it the first choice for high-quality and high-volume printing applications.

The following PS and CTP plate may interest you

Further reading: ctp thermalctp thermal platepositive thermal ctp platethermal ctpthermal ctp machinethermal ctp platethermal ctp systems