Types of CTP plates

Jun. 27, 2025

CTP Plate, or Computer-to-Plate technology, is one of the core technologies in modern printing. As the key carrier of this technology, CTP plates directly determine print quality, production efficiency, and cost control.

There are many types of CTP plates to meet printing durability, cost, environmental impact, and application needs. The main types include thermal plates, violet plates, photopolymer plates, process-free plates, and material-specific plates (aluminum/polyester). The choice depends on factors such as run length, printing quality requirements, and sustainability goals, ensuring flexibility for industries such as commercial printing, packaging, and newspapers.

Basic Requirements for CTP Plates

For high-quality printing CTP systems, the plates must meet the following key requirements:

- High sensitivity: Capable of completing the exposure process in a short time, improving production efficiency

- Good resolution: Ensures sharp and clear dots, capable of reproducing fine image details

- Strong dot reproduction ability: Accurately reproduces 1%–99% dots to ensure complete tonal range

- High run length: Withstands a large number of prints without damage, reducing the frequency of plate changes

- Easy to handle: Simplifies the platemaking process, reducing operational difficulty and cost

- High contrast: Ensures a clear boundary between image and non-image areas

How many types of CTP plates are there?

CTP Plates are mainly classified into photosensitive systems and thermal systems based on their imaging mechanisms, along with other derivative types.

CTP Plates by Imaging Technology

| Imaging Principle | Type of CTP Plate | Mechanism | Characteristics | Application Fields |

| Thermal Plate | Thermal CTP Plate | Uses 830 nm infrared laser to generate heat on the plate surface, causing chemical changes in the coating to form an image. Post-exposure processing may involve chemical or chemical-free methods. | Suitable for long-run printing, strong printing durability | Applicable to commercial printing, high-end packaging printing, large-volume book and newspaper printing that require long-run prints. |

| Less affected by ambient light, can be operated in daylight | ||||

| High dot reproduction accuracy and image quality | ||||

| Long shelf life and good storage stability | ||||

| Photosensitive Plate | Violet CTP Plate | Uses 405–410 nm violet laser to expose the coating on the plate, followed by chemical or chemical-free development to form the image. | Fast imaging speed, improved printing efficiency | Suitable for brochures, magazines, flyers, short-run commercial printing, and newspaper printing. |

| Lower equipment cost, reduced operating expenses | ||||

| Suitable for short to medium-run printing | ||||

| Long laser lifespan, low energy consumption | ||||

| Traditional UV/Photopolymer CTP Plate | Uses UV light or laser of specific wavelengths to cure photopolymer coating, hardening the exposed area to form the image. | High durability, suitable for high-volume printing | Mainly used in flexographic printing, widely applied in label printing, flexible packaging, corrugated packaging, especially in food and pharmaceutical packaging industries. | |

| Wide ink adaptability, compatible with various flexographic inks | ||||

| Allows for chemical-free or low-chemical processing, more environmentally friendly | ||||

| Suitable for different substrates (such as films, metal foils, etc.) | ||||

| Silver Halide CTP Plate | Top layer is silver halide emulsion, underlayer is physical nucleation layer. After laser exposure, a diffusion transfer reaction occurs in the developer, where silver ions are reduced to metallic silver on the nucleation layer forming hydrophobic images. Non-image areas remain hydrophilic. | Very fast plate making speed | Suitable for medium to long-run jobs requiring high resolution and easy operation. | |

| Extremely high resolution | ||||

| Requires special chemical processing (usually includes development and fixing steps) | ||||

| Relatively lower printing durability | ||||

| High cost, less environmentally friendly, market share is very small now | ||||

| Others | Process-Free CTP Plate | No chemical or water processing needed after imaging; can be directly mounted on press for printing. Typically a special implementation of thermal or photosensitive type. | Most environmentally friendly (zero emissions), simplest operation, space-saving (no processor required) | Suitable for newspaper printing, short-run commercial printing, high-speed and eco-friendly quick printing markets. |

| Generally higher cost, requires more precise control of ink-water balance on press | ||||

| Needs ongoing optimization for durability, ink uptake speed, and scumming resistance | ||||

| UV-CTP Plate | Plates designed for CTcP (Computer-to-Conventional Plate) technology. CTcP uses high-intensity UV light (e.g., UV-LED or mercury lamp) and digital micromirror device (DMD) imaging. | Lower plate cost | Specifically for CTcP technology; conventional positive or negative PS plates can be used with CTcP. | |

| Relatively slower plate-making speed | ||||

| Slightly lower resolution compared to laser CTP; still requires chemical development | ||||

| Inkjet CTP Plate | Hydrophilic substrate; special ink is directly printed onto the base by an inkjet printer to form image areas. Post-processing may involve curing (e.g., UV curing) before printing. | Very low equipment cost, truly chemical-free | Applied in small offset printing, quick print jobs, customized plate making, and proofing. | |

| Very suitable for ultra-short runs, proofing, rapid plate changes | ||||

| Low printing durability, limited resolution, generally lower print quality than laser CTP, slower speed |

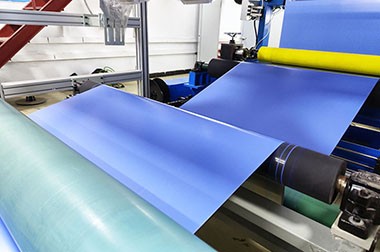

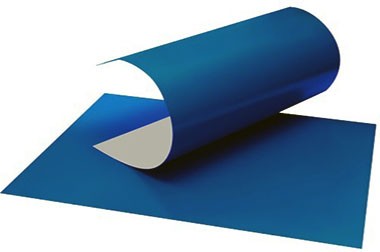

Thermal CTP Plate

Thermal CTP plates are among the most widely used types of CTP plates on the market today. They offer high resolution and excellent dot reproduction capabilities. Thermal CTP plates are primarily composed of a high-quality grained and anodized aluminum base and a thermal photosensitive layer.

Key Technical Parameters of Thermal CTP Plate

| Parameter Name | Parameter Range | Technical Features |

| Sensitivity Wavelength | 800–850 nm, peak at 830 nm | Sensitive to infrared laser, operable under daylight |

| Exposure Energy | 100–250 mJ/cm² | Varies by plate model |

| Resolution | 1–99% @200–450 lpi | Capable of extremely fine dot reproduction |

| Run Length | 20,000–1,000,000 impressions | Can exceed 1 million impressions after baking |

| Safe Light Conditions | Operable under natural light or yellow safe light | Convenient operation, no darkroom required |

Technical Advantages of Thermal CTP Plate

The dot reproduction of thermal CTP plates is considered the best among all CTP plates. Dot edges are sharp and clear, making it easier to achieve ink-water balance during printing and ensuring good press compatibility.

Violet CTP Plate

Violet laser CTP plates have rapidly developed in recent years, known for their high sensitivity and user-friendly operation environment. These plates are mainly composed of multi-grain aluminum bases and photopolymer photosensitive layers; some high-end products use a three-layer coating technology.

Key Technical Parameters of Violet CTP Plate

| Parameter Name | Parameter Range | Technical Features |

| Sensitivity Wavelength | 400–410 nm, peak at 405 nm | Sensitive to violet laser, narrow spectral response |

| Exposure Energy | Relatively low, exact value depends on the product | Designed for high sensitivity, high productivity in plate making |

| Resolution | 1–99% @175–250 lpi | Low dot gain, suitable for high-quality commercial printing |

| Run Length | 200,000–400,000 impressions | Achieves high run length without baking |

| Safe Light Conditions | Operable under yellow safe light | Provides a brighter working environment |

Technical Advantages of Violet CTP Plate

A notable advantage of violet laser CTP plates is the ability to use yellow safe lights. Since violet plates are not sensitive to red and green light, yellow safe lights provide a brighter working environment and make operations more convenient.

Silver Halide CTP Plate

Silver halide CTP plates are one of the earlier types of CTP plates, known for their high sensitivity and excellent imaging quality. They are primarily composed of a roughened aluminum substrate, a silver halide emulsion layer, and a physical development layer.

Key Technical Parameters of Silver Halide CTP Plate

| Parameter Name | Parameter Range | Technical Features |

| Sensitivity Wavelength | Wide spectral response | Compatible with various laser light sources |

| Exposure Energy | 1–3 μJ/cm² | Extremely high sensitivity; the highest among all CTP plates |

| Resolution | 1–99% @200–300 lpi | Excellent dot reproduction; screen ruling up to 300 lpi |

| Run Length | 250,000–400,000 impressions | Typically not less than 250,000 impressions; suitable for medium to long runs |

| Safe Light Conditions | Requires darkroom operation | Highly light-sensitive; strict environmental requirements |

Technical Advantages of Silver Halide CTP Plate

Silver diffusion-type CTP plates offer extremely high photosensitivity, below 1 μJ/cm², making them the most sensitive among all CTP plate types. Their dot reproduction is excellent, capable of achieving 1%–99% dots at 200 lpi screen ruling.

Inkjet CTP Plate

Inkjet CTP plates represent a relatively new CTP technology, combining inkjet technology with traditional CTP plate-making processes. These plates are typically created by applying an ink-receptive coating on standard plates or using specially treated aluminum substrates.

Key Technical Parameters of Inkjet CTP Plate

| Parameter Name | Parameter Range | Technical Features |

| Imaging Method | Inkjet imaging | Specialized inkjet heads spray ink directly onto the plate surface |

| Resolution | 150–175 lpi | Meets low to mid-range quality needs; fine dots down to 2% achievable |

| Run Length | 20,000–100,000 impressions | With coated plates: 50,000–100,000; up to 100,000–150,000 after baking |

| Plate Type | Multiple options available | PS plates, uncoated aluminum, or coated paper, etc. |

| Processing Workflow | Simplified process | Inkjet → Exposure → Development → Printing; simple workflow |

Technical Advantages of Inkjet CTP Plate

Inkjet CTP plates replace traditional laser exposure with inkjet imaging, offering low cost and easy operation. A key advantage is a 30%–50% reduction in prepress plate-making costs, eliminating the need for darkrooms and laser imagesetters.

CTP Plates by Material Composition

| CTP Plate Type | Mechanism | Advantages | Disadvantages | Application Areas |

| Aluminum CTP Plate | Uses high-purity aluminum plate as the substrate, coated with a photosensitive layer on the surface. After exposure, an image is formed for printing, and the unexposed parts are removed through development or process-free technology. | - High mechanical strength, not easily deformed, suitable for high-speed printing - Strong durability, capable of handling large-volume printing demands - High image resolution, capable of reproducing fine dots, meeting high-quality printing requirements | - Higher production cost, requiring a larger initial investment compared to polyester plates - Requires specific exposure and processing equipment, making the operation more complex | Suitable for offset printing, widely used in high-quality printing applications such as commercial printing, packaging printing, book and magazine printing. |

| Polyester CTP Plate | Uses polyester film as the substrate, coated with a photosensitive layer on the surface. After exposure, an image is formed, suitable for small printing presses or cost-sensitive printing needs. | - Lightweight, suitable for small printing equipment, no need for specialized printing machines - Cost-effective, ideal for budget-conscious printing needs - Easy to operate, suitable for short-run printing, improving flexibility | - Lower durability, not suitable for long-term high-load printing - Poor dimensional stability, which may affect printing accuracy - Lower image quality compared to aluminum CTP plates, making it difficult to achieve ultra-high-precision printing | Suitable for short-run digital printing, small-batch commercial printing, ticket printing, and small printing machines, such as those used in offices or small quick-print shops. |

CTP Plate Applications

| Type of CTP Plate | Application Scenario | Description |

| Thermal CTP Plate | High-End Commercial Printing | Suitable for premium brochures, art reproductions, luxury packaging, and other prints requiring extremely fine dot reproduction and high color accuracy. |

| Packaging Printing | Ideal for long-run printing of food and pharmaceutical packaging; run length can exceed 1 million impressions. | |

| Newspaper Printing | Although cost-sensitive, thermal CTP’s high stability and fast plate-making make it competitive in high-quality newspaper printing. | |

| Violet CTP Plate | Commercial Printing | Suitable for commercial advertisements, brochures, and product catalogs where high quality is needed but extreme run length is not required. |

| Newspaper Printing | High sensitivity meets tight deadlines; suitable for quality-focused newspaper printing. | |

| Commercial Web Printing | Well-suited for stable printing in high-speed environments such as commercial web offset advertising. | |

| Silver Halide CTP Plate | High-Quality Commercial Printing | Extremely high resolution; ideal for jobs demanding precise dot reproduction; up to 300 lpi screen ruling. |

| Medium to Long Run Printing | Run length ≥250,000 impressions; ideal for commercial applications requiring medium to high volumes. | |

| Special Plate-Making Needs | Suitable for non-standard printing needs such as high-resolution dots, special light source compatibility, and fast plate production. | |

| Inkjet CTP Plate | Small to Medium-Sized Printing Enterprises | Low-cost digital plate-making reduces prepress costs by 30%–50%; suitable for startups and regional print shops. |

| Short-Run Printing | Cost-effective for 20,000–100,000 impressions; coated plates achieve 50,000–100,000 prints. | |

| Digital Proofing | Supports direct plate making, daylight imaging, color inkjet proofing, and digital proofing; suitable for small, diverse printing needs. |

CTP Plate Selection Recommendations

Key Factors in CTP Plate Selection

Choosing the right CTP plate is a critical decision for printing companies and requires comprehensive consideration of multiple factors:

Main Considerations

- Printing Quality Requirements: For products requiring high precision dot reproduction and high color fidelity, thermal or violet CTP plates should be prioritized.

- Print Volume Requirements: For long-run printing, choose thermal plates with high durability; for medium to long runs, silver halide or violet plates are suitable; for short-run printing, inkjet CTP plates are ideal.

- Cost Considerations: Includes plate cost, equipment cost, operating cost, and labor cost.

- Production Efficiency: Plate-making speed, registration accuracy, and continuous operating capability.

- Environmental Requirements: Processless thermal plates require no chemical processing and are the most environmentally friendly option.

- Operating Environment: Violet plates can be operated under yellow safe light, offering a brighter working environment.

Plate Selection Recommendations for Different Types of Printing Companies

-

Large Commercial Printing Enterprises

Recommended to use thermal CTP plates, especially processless thermal plates. These plates offer excellent dot reproduction and extremely high durability, with run lengths exceeding 1 million impressions after baking.

-

Medium-Sized Comprehensive Printing Enterprises

Recommended to use violet CTP plates. These plates feature high sensitivity and fast plate-making speed, suitable for medium-volume printing needs.

-

Small Printing Enterprises

Recommended to use inkjet CTP plate systems. These systems offer low equipment investment, plate costs similar to standard PS plates, and simple operation.

-

Newspaper Printing Enterprises

Recommended to use violet CTP plates. These plates offer high sensitivity and fast imaging, meeting the tight deadlines of daily newspapers.

Plate Selection Recommendations for Special Printing Requirements

| Special Requirement | Recommended Plate Type | Main Advantages |

| UV Ink Printing | Baked Thermal CTP Plate | Run length up to 50,000 impressions |

| Printing on Rough Paper | High Durability Thermal CTP Plate | High run length and excellent water-ink balance properties |

| High-Precision FM Screening | Thermal or Violet CTP Plate | Supports FM dot output as small as 10μm |

| Environmentally Friendly Printing | Processless Thermal CTP Plate | No chemical processing, no chemical discharge |

| Frequent Content Changes | Inkjet CTP Plate | Low cost and fast plate-making |

| Long-Run Printing Needs | Baked Thermal CTP Plate | Run length can exceed 1 million impressions |

CTP vs. CTCP

You may also encounter CTCP plates. These are produced on traditional pre-sensitized (PS) plates rather than the specially coated plates used in true CTP. Although they share some similarities with CTP plates, they are generally considered a separate category due to differences in coating technology and processing.

Each type has its own balance of sensitivity, speed, durability, and cost, and can be further subdivided into specialized subtypes to meet different production requirements.

Users viewing this material also viewed the following

Further reading: ctp platectp machinectp plate making machinecomputer to plate ctpctp printingctp computerctp computer to platectp computer to plate machinectp machine for printingplate ctpctp printing platectp plate machineviolet ctp platesviolet ctp machine