What is the difference between CTP plate and PS plate?

Apr. 18, 2025

The main difference between CTP plates and PS plates is that CTP plates are imaged directly from digital files, offering excellent precision, dot reproduction, and efficiency, while PS plates rely on traditional film-based processes, which have lower precision and involve more manual steps.

There are significant differences between CTP (Computer to Plate) and PS (Pre-Sensitized) plates in offset printing, covering aspects such as technology, workflow, performance, and application.

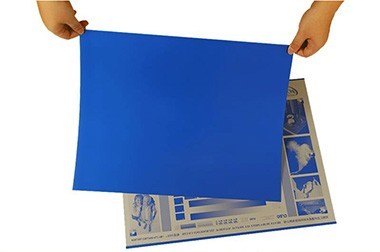

CTP (Computer to Plate) and PS (Pre-Sensitized) represent two different plate-making methods in offset printing. CTP plates use laser systems to image directly from digital files without the use of film, while PS plates rely on a film-based ultraviolet exposure workflow. This fundamental difference leads to substantial variations in resolution, substrate requirements, workflow steps, chemical usage, cost, and environmental impact.

CTP (Computer-to-Plate) plates and PS (Pre-sensitized) plates are widely used in the printing industry, each with unique characteristics suited for specific applications. However, CTP plates have largely replaced traditional PS plates due to their superior performance.

Comparison Table of CTP Plate and PS Plate

| Comparison Item | CTP Plate | PS Plate |

| Dot Reproduction Ability | Capable of reproducing a tone range from 1%–99%, accurately reproducing intricate details | Difficult to reproduce fine dots, affecting high-precision printing results |

| Ink Balance | Excellent ink balance with minimal fountain solution, producing vibrant and consistent colors | Requires more fountain solution, diluting ink brightness and affecting color consistency |

| Registration Accuracy and Waste Reduction | Direct transfer from digital design, high registration accuracy, minimal paper waste | Relies on traditional film, large registration errors, numerous test runs, more material waste |

| Cleanliness and Print Quality | Plate surface is almost free from dirt, printing is clean and sharp, requiring minimal manual correction | Plate surface has more surface flaws, requiring additional cleaning and adjustments, affecting printing efficiency and quality |

| Emulsification and Edge Sharpness | Excellent water-ink balance, minimal ink emulsification, sharp and clear edges | More prone to ink emulsification, edges are less sharp, with slight loss of details |

CTP Plate and PS Plate Plate-Making Process

CTP Plate vs PS Plate Plate-Making Method

- PS Plate: Uses traditional chemical processes, requiring film exposure, development, and fixing steps to complete the plate-making. The process involves multiple steps and relies heavily on manual operation.

- CTP Plate: Based on digital technology, the computer directly controls the laser to image on the plate material, eliminating the film step and part of the chemical processing, enabling fully automated plate-making.

CTP Plate vs PS Plate Production Process Complexity

- PS plates undergo complex procedures such as film making, exposure, and development, and are prone to issues like dirt spots and film scratches due to environmental dust or operational errors.

- CTP plates are directly output by machines, reducing human intervention and intermediate steps, resulting in higher stability.

| Item | CTP Plate (Computer To Plate) | PS Plate (Pre-Sensitized Plate) |

| Imaging Method | Direct laser imaging (thermal, UV, photopolymer) | Ultraviolet exposure through intermediate film |

| Laser Type | Typically infrared laser (800–850nm) | Not suitable for direct laser, requires film |

| Plate Structure | Photosensitive layer (can be thermal, photopolymer, etc.) | Aluminum base: anodized layer + hydrophilic layer + photosensitive layer |

| Intermediate Steps | No film required, directly output from digital file | Requires intermediate film for exposure |

| Photosensitive Type | Thermal (thermal ablation, thermal crosslinking, silver halide) | Ultraviolet photosensitive materials |

| Development Process | Generally uses chemical or chemical-free processing (depending on plate type) | Requires chemical development after exposure to remove unexposed areas |

| Plate Type | Mainly negative type (exposed area retained) | Divided into positive type (exposed area dissolves) and negative type (exposed area retained) |

| Process Advantages | High precision, high degree of automation, saves time and materials | Mature process, lower cost, but complex workflow |

| Common Applications | Commercial printing, newspaper printing, fine printing | Traditional printing, low-cost publishing printing |

CTP Plate and PS Plate Imaging Technologies

Direct Imaging vs Indirect Imaging

- CTP systems expose plates directly from rasterized digital files, guiding laser engraving of the image without any intermediate film.

- PS plates require physical film production (via imagesetters), which is then clamped onto a pre-sensitized plate and exposed to UV light in a vacuum frame.

CTP Plate vs PS Plate Exposure Methods

- Most CTP workflows use infrared (IR) or UV lasers (e.g., 830 nm thermal or 400 nm UV lasers) to ablate or harden polymer layers, producing extremely sharp dots with minimal dot gain.

- PS plates are exposed under broad-spectrum UV lamps through film, introducing scattered light and energy loss, which reduces edge sharpness.

Chemical Composition of CTP and PS Plates

CTP Plate vs PS Plate Photosensitive Layers

CTP plates typically use thermosensitive or pure photosensitive polymer coatings that directly react with laser energy, enabling "process-free" plates without wet chemical treatment.

PS plates have a multilayer structure, including anodized aluminum base, hydrophilic layer, photosensitive layer, and roughened surface, requiring chemical development after UV exposure.

PS plate developer has a pH of about 12, while CTP developer is usually 3–4 times more alkaline for rapid polymer removal.

CTP Plate vs PS Plate Aluminum Substrate Requirements

- CTP substrates require stricter geometric tolerances: thickness around 0.280 mm (±0.005 mm), width tolerance ≤±0.5 mm, and surface roughness Ra of 0.45–0.60 μm.

- PS plates use slightly thinner substrates (approx. 0.270 mm ±0.005 mm), with roughness of 0.60–0.80 μm; looser specifications are allowed due to the film-based imaging process.

CTP vs PS Plate Resolution and Print Quality

CTP Plate vs PS Plate Dot Reproduction

- CTP plates can reproduce 1% to 99% tonal range and maintain excellent detail in highlights and shadows.

- PS plates struggle with very fine dots, limiting high-resolution reproduction and subtle gradients.

CTP vs PS Plate Stability

- PS plate quality varies significantly between batches, with poor long-term stability.

- CTP plates undergo strict quality control, have high run lengths, and are suitable for long-run printing.

CTP Plate vs PS Plate Edge Sharpness and Registration

- Laser imaging in CTP produces sharp edges, minimal dot gain, and high registration accuracy, reducing setup waste.

- PS workflows involve film alignment and UV exposure, introducing registration errors and requiring more test runs and manual adjustments.

CTP Plate vs PS Plate Workflow Efficiency

Prepress Workflow

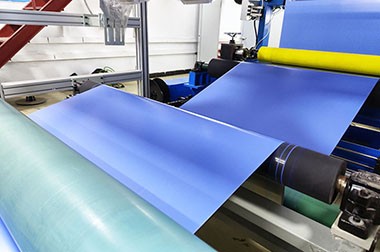

- Typical CTP workflows skip film output and vacuum frame setup, going directly from RIP to plate, reducing turnaround time and manual steps.

- PS workflows involve film output, inspection, vacuum framing, UV exposure, and development, increasing time and labor.

Chemical Processing

- Many modern process-free CTP plates allow the dampening solution on the press to remove unexposed areas, eliminating the need for plate processors.

- PS plates require separate developer, fixer, and often gum solution, in addition to wastewater treatment of spent chemicals.

CTP Plate vs PS Plate Operating Costs

- CTP imagesetters and laser plate setters require higher upfront investment, but savings from eliminating film, reduced chemical use, and faster turnaround lower per-plate costs over time.

- PS systems have lower capital cost, but ongoing expenses for film, chemicals, maintenance, and storage increase long-term operating costs.

CTP plates offer a fully digital, filmless workflow with superior resolution, registration accuracy, and efficiency, making them ideal for high-volume, high-quality offset printing. PS plates are still used where capital investment is limited or infrastructure supports film workflows, but they entail higher costs, lower precision, and greater chemical handling.

How to Choose Between CTP Plate and PS Plate

Choose CTP Plate: Suitable for companies pursuing high quality, high efficiency, environmentally friendly processes, and large order volumes.

Choose PS Plate: Suitable for companies with a limited budget, moderate quality requirements, or many traditional printing projects.

| Criteria for Selection | CTP Plate | PS Plate |

| Print Quality Requirements | Suitable for high-precision, high-quality printing, such as catalogs, packaging, and advertising printing, capable of reproducing fine details and complex tones. | Suitable for general printing needs, such as books, newspapers, or low-cost printing, with relatively lower quality requirements. |

| Cost Budget | Higher initial investment (such as CTP plate-making machines and software), but long-term reduction in material waste and labor costs, suitable for large-volume, high-frequency printing. | Lower equipment and material costs, suitable for small to medium-sized enterprises or low-frequency printing projects. |

| Efficiency and Production Cycle | Digital plate-making process, fast plate-making speed, reduces manual intervention, suitable for orders that require quick turnaround, significantly improving production efficiency. | Requires traditional film-based plate-making procedures, which are more complex, resulting in a longer production cycle and affecting delivery speed. |

| Environmental and Material Waste | Excellent environmental performance, minimal paper waste, low fountain solution usage, meeting modern green printing demands. | More waste, especially during registration adjustment and testing, with high fountain solution usage, not environmentally friendly. |

| Technical Support and Operation Skills | Requires skilled personnel familiar with digital workflows and CTP plate-making equipment and maintenance, suitable for enterprises with modern technical support. | Lower technical requirements for operators, easily adopted by traditional printing plants, suitable for enterprises lacking modern equipment support. |

Advantages of CTP Plate Compared to PS Plate

CTP plates offer superior dot reproduction, registration accuracy, and cleaner printing with better ink-water balance, while PS plates rely on traditional film-based methods with lower precision and more manual adjustments.

- Excellent dot reproduction and detail accuracy

- Better ink-water balance and vibrant colors

- Higher registration accuracy, reducing paper waste

- Cleaner plates with minimal manual adjustments

- Sharper edges and enhanced print quality

Users viewing this material also viewed the following

Further reading: ctp platectp machinectp plate making machinecomputer to plate ctpctp plates for offset printingctp printingctp computerctp computer to platectp computer to plate machinectp machine for printingctp offset machinectp offset printingctp offset printing platesctp plate machinectp printing platectp thermalctp thermal plateoffset ctpoffset printing ctp plateplate ctppositive thermal ctp platesmall ctp machinethermal ctpthermal ctp machinethermal ctp platethermal ctp systems