What is CTP in Offset Printing?

Aug. 06, 2025

CTP, or Computer-to-Plate, is a technology used in offset printing that transfers digital images directly onto printing plates without the need for film. This innovation greatly simplifies the prepress workflow, improving both print quality and efficiency.

CTP in Offset Printing

In traditional offset printing, images are first created on film, and then plates are made from the film. This multi-step process can be very time-consuming and prone to errors.

CTP eliminates the film stage by directly creating plates from digital files. The digital artwork is processed using specialized software, and the output is a plate ready for printing.

Types of CTP Systems

- Thermal CTP: Uses thermal laser exposure to create plates. The areas exposed to the laser become more ink-receptive, while unexposed areas are washed away during development.

- UV CTP: Uses ultraviolet light to expose plates. This method is beneficial for certain types of plates and can offer faster processing times.

- Inkjet CTP: Some systems use inkjet technology to directly create images on the plates. This method is less common but can be used for specific applications.

- Internal Drum Type: The printing plate is mounted on a rotating drum, while the laser or light source remains stationary.

- External Drum Type: The printing plate is wrapped around the outer drum, and the imaging head moves to expose the image.

- Flatbed Type: The printing plate is laid flat, and the laser beam exposes the image line by line.

-

Positive Thermal CTP Plate

Positive Thermal CTP Plate is a type of digital plate-making technology used in the printing industry, widely applied in printing production, especially under the demand for high-quality printing and rapid production.

-

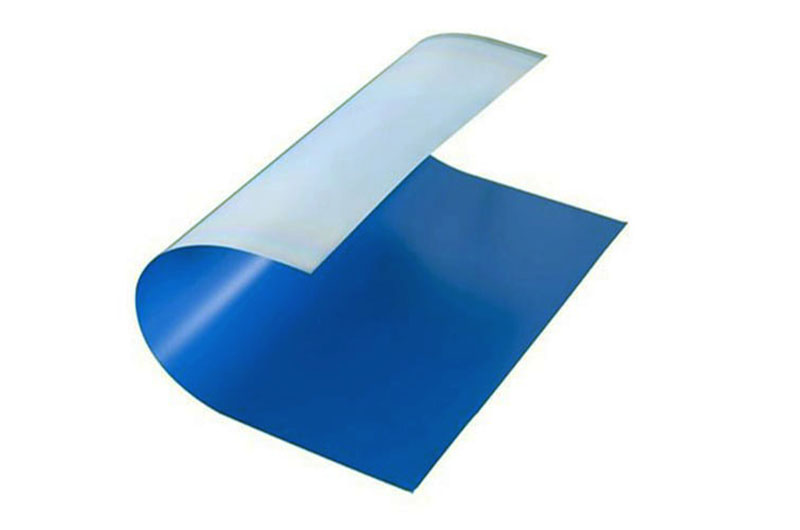

Positive UV-CTP Plate

The Positive UV-CTP Plate is a plate material specifically designed for the printing industry, utilizing ultraviolet (UV) technology for image generation in computer-to-plate (CTP) systems.

-

Thermal CTP Plate(Process-less)

The process-free thermal CTP plate is a thermal printing plate that does not require chemical processing or any post-exposure steps after imaging, making it the simplest method of plate making.

-

Thermal CTP Plate (Double Layer)

Double Layer Thermal CTP Plate is made of two layers, the top layer is photosensitive material and the bottom layer is heat-resistant material. It is widely used in the printing industry due to its excellent image reproduction quality and efficiency.

-

Thermal CTP plate (Single-layer)

Single-layer thermal CTP plates are capable of producing high-resolution images, making them suitable for fine and high-quality printing applications.

Advantages of CTP

- High Precision: CTP technology provides higher image precision than traditional film-based platemaking, with clearer details.

- High Efficiency: By eliminating traditional platemaking steps (such as exposure, development, and imposition), the platemaking speed of CTP is significantly faster, reducing time costs.

- Environmentally Friendly: CTP eliminates the chemicals used in traditional platemaking, reducing waste liquid discharge and being more environmentally friendly.

- Cost Savings: CTP reduces material waste and labor costs, lowering overall production expenses.

- Precise Control: The digital nature of CTP reduces human errors, allowing for more precise control over image output.

Applications of CTP in Offset Printing

CTP is widely used in commercial printing, packaging, and publishing. It is especially beneficial for large-volume print jobs where quality and efficiency are critical.

Digital printing technologies are also increasingly integrated with CTP systems to further enhance functionality.

A CTP system consists of various components, including computers, imaging devices (such as lasers), plate processors, and plate mounting systems. The integration of these components is crucial for achieving optimal performance.

CTP in offset printing represents a major advancement in the printing industry, providing a faster, more efficient, and higher-quality method for producing printing plates. This technology has become standard practice in many printing operations and has significantly improved the overall printing production process.

CTP Technology Workflow

- Digital Image Processing: In CTP technology, images are first digitally processed on a computer, typically using specialized design and layout software. Image files are usually in formats such as PDF, TIFF, or EPS.

- Image Output to Printing Plate: The processed digital image is directly output to a printing plate. Printing plates are typically made of aluminum and are coated to carry the printed image. The CTP system uses a laser beam (or other methods) to expose the plate, transferring the image information accurately onto the surface of the plate.

- Development and Washing: After exposure, the printing plate goes through a development and washing process. During development, unexposed areas are washed away, leaving the exposed areas to form the image. This process is similar to the plate-making operation in traditional film-based platemaking.

- Drying and Mounting: The processed printing plate is dried and mounted on the printing press, ready to begin printing.

Traditional vs. CTP Printing

In traditional offset printing, digital files are first output onto film, which is then used to create the printing plate. CTP eliminates the film stage and images the plate directly from the digital file.

Process Differences: Traditional vs. CTP Printing

Traditional Plate Making

Digital file → Film output (using an imagesetter to record text and graphics onto film) → Film inspection → Plate exposure (using the film as a "master" to transfer the image onto the plate via exposure) → Development and other post-processing → Plate completed.

Key point: Requires film as an intermediate carrier; the process is lengthy and involves many steps.

CTP Printing

Digital file → Directly drive the CTP device (via laser or other light source) → Image directly onto the plate surface (no film required) → Development and other post-processing → Plate completed.

Key point: Eliminates the steps of film output, storage, inspection, and exposure, making the process more straightforward.

Quality Differences: Traditional vs. CTP Printing

Traditional Plate Making

Films may suffer from scratches, dust contamination, or dimensional changes due to environmental temperature and humidity, leading to image inaccuracies; during plate exposure, film-to-plate alignment precision and exposure uniformity also affect the final plate quality, which can result in dot loss and tonal banding issues.

CTP Printing

Direct imaging via digital signals reduces errors from the film process, achieving higher dot reproduction accuracy (up to 1%–99% dot reproduction), finer tonal gradation, and more stable plate quality—especially suitable for high-precision printing (e.g., packaging, brochures).

Efficiency Differences: Traditional vs. CTP Printing

Traditional Plate Making

Film output, inspection, and plate exposure must be performed step-by-step, and producing a single plate set takes a long time (usually 1–2 hours); if there is an error in the film, it must be re-output and the process repeated, causing production delays.

CTP Printing

The time from digital file to plate is significantly shortened (a single plate set can be completed within 30 minutes); if the digital file is modified, plates can be remade directly, enabling faster response—especially suitable for short-run printing, rush jobs, or variable data printing.

Cost Differences: Traditional vs. CTP Printing

Traditional Plate Making

Requires investment in film (silver halide or polyester materials), imagesetters, etc., and films are consumables with high long-term usage costs; additionally, film storage and disposal (containing heavy metals) add hidden costs.

CTP Printing

Initial equipment investment is higher (CTP platesetters are more expensive than imagesetters), but film and related consumables are eliminated, resulting in lower long-term total cost; simplified workflow also reduces manual labor, indirectly lowering labor costs.

Environmental Differences: Traditional vs. CTP Printing

Traditional Plate Making

Films contain silver halide, and developers contain chemical pollutants, which can cause environmental harm when discarded and do not align with green printing trends.

CTP Printing

No need for film, reducing chemical waste discharge; some CTP plates use environmentally friendly developers (or even process-free technology), better meeting environmental protection requirements.

By eliminating the film stage, CTP outperforms traditional plate making in terms of quality, efficiency, cost, and environmental impact, and has become the mainstream technology in modern offset printing; traditional plate making is only used in a few scenarios involving outdated equipment or extremely low-cost demands, and is gradually being replaced by CTP.

Although the initial investment in CTP equipment may be relatively high, the long-term cost savings and efficiency gains usually make it a worthwhile investment for printing companies.

Further reading: ctp plates for offset printingctp offset machinectp offset printingctp offset printing platesoffset ctpoffset printing ctp plateoffset printing plate making machine