CTP and CTCP: Choosing for Different Printing Needs

Mar. 06, 2025

Computer-to-plate (CTP) prepress imaging equipment is mainly divided into two categories: regular CTP and CTcP. Although both processes eliminate the film-making step and utilize digital information for "prepress production—data transmission—direct plate making."

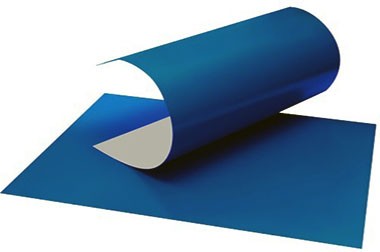

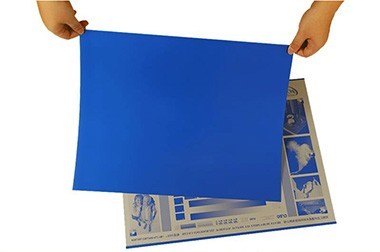

Different Exposure Materials Used in CTCP and CTP

There are significant differences in exposure materials between CTcP and CTP. CTcP uses ordinary photosensitive PS plates to image digital information, while CTP uses special CTP plates coated with a unique photosensitive layer for imaging. These specialized plates better adapt to digital technology, providing higher printing quality and precision.

Printing Process

CTcP is typically used for color printing, emphasizing color accuracy and consistency, whereas CTP focuses more on improving production efficiency and print quality.

CTCP (Computer-to-Color-Print)

- Color Accuracy: The CTcP system uses specialized color management software to ensure accurate reproduction of colors in the output process. It employs advanced color calibration technology to maintain color consistency across every print, making it particularly suitable for color printing with strict brand requirements.

- Printing Technology: CTcP often utilizes digital inkjet or laser technology to directly convert digital files into printed products. This process typically involves high-resolution image processing, ensuring clarity in detail and color.

- Flexibility: Since CTcP does not require plate making, it can quickly respond to market demands, making it suitable for short runs or personalized printing.

CTP (Computer-to-Plate)

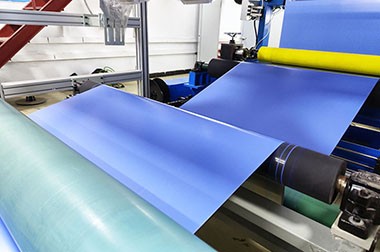

- Production Efficiency: The CTP system significantly enhances production efficiency. Through automated processes, it reduces the time and labor required for traditional plate-making, especially excelling in large-scale production.

- Print Quality: The digital technology used in the plate-making process of CTP can produce high-quality plates, ensuring accurate color reproduction and detail clarity during printing. These plates typically have better durability and longer lifespan.

- Consistency: CTP systems maintain consistent quality throughout the printing process by precisely controlling each plate. This consistency is crucial for large commercial projects.

Application Scenarios

CTcP is commonly used in situations requiring high-quality color printing, such as magazines and advertisements, while CTP is more broadly applied in various types of printing, including commercial and packaging printing.

Application Scenarios for CTCP

- High-Quality Color Printing: CTcP is particularly suitable for printing projects requiring high quality and color accuracy, such as magazines, advertisements, brochures, and packaging design. These projects typically have high demands for color performance, making CTcP's color management capabilities especially important.

- Short Run Printing: In rapidly changing market demands, CTcP can quickly respond, making it suitable for small batches and short-cycle printing needs. Personalized products and limited edition items also commonly utilize CTcP technology.

- Art and Photography Printing: CTcP is widely applied in art printing and high-end photography due to its ability to meet high standards in color and detail.

Application Scenarios for CTP

- Commercial Printing: CTP is widely used in the commercial printing field, such as newspapers, magazines, brochures, and advertising materials. These projects typically require large-scale production and emphasize efficiency and cost-effectiveness.

- Packaging Printing: CTP also holds a significant position in the packaging industry. Whether for food packaging, pharmaceutical packaging, or cosmetics packaging, CTP can deliver the required print quality and efficiency.

- Long Run Printing: For printing projects that require large-scale production, CTP's efficiency and consistency make it the preferred choice, especially for longer print cycles, significantly reducing unit costs.

Different Exposure Technologies in CTCP and CTP

The following is a comparative table of the differences in exposure technology between CTcP and CTP:

| Feature | CTCP | CTP |

| Exposure Light Source | Short arc UV high-pressure mercury lamp | Laser |

| Imaging Technology | Digital halftone imaging technology | Traditional exposure technology |

| Drive Method | Magnetic levitation drive | Mechanical transmission |

| Exposure Head Structure | Composed of high-precision optical components and electronic sensing devices | Mainly relies on laser emitters |

Users viewing this material also viewed the following

Further reading: ctp plates for offset printingctp printingcomputer to plate printingctcp printing platesctp machine for printingctp offset printingctp offset printing platesctp printing plateoffset printing ctp plateoffset printing plate making machineplatesetter printingctcp plate making machinectcp plate