Computer to Plate CTP

Aug. 06, 2025

Computer to Plate (CTP) is a digital imaging technology used in the printing industry that directly transfers digital designs onto printing plates, eliminating the need for a film intermediary. This method simplifies the prepress process, improving efficiency, accuracy, and environmental sustainability.

Computer to Plate (CTP) works by transferring the image directly from the computer to the printing plate. CTP technology eliminates intermediate steps, reducing the likelihood of errors and significantly enhancing efficiency, quality, and cost-effectiveness.

Compared to traditional Computer to Film (CTF) methods, Computer to Plate (CTP) does not require film as an intermediary, further optimizing the production process.

How Computer to Plate CTP Works

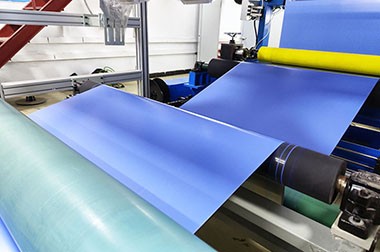

In the Computer to Plate (CTP) process, digital files are directly transmitted to the plate-making equipment, which uses laser technology to precisely etch the image onto the printing plate. This direct imaging method eliminates the film-making step in traditional processes, not only shortening production cycles but also significantly reducing the risk of errors caused by film handling. After the image is etched, the plate undergoes a developing process and is ready for use in the printing press.

Advantages of Computer to Plate CTP

-

Improved Image Quality:

Computer to Plate (CTP) eliminates potential errors in the traditional film process by directly transferring digital images onto the plate surface. Traditional film methods can lead to issues such as dot gain, image blurring, or quality loss, while the CTP system, by directly printing, allows for precise control over dot size and arrangement, improving image sharpness. In this way, CTP ensures more accurate image details and smoother, sharper printed results, significantly enhancing the overall quality of the final print.

-

Faster Turnaround Time:

Computer to Plate (CTP) makes the prepress workflow more efficient. By eliminating the traditional film-making process, CTP removes the steps of film processing and exposure, shortening the entire prepress cycle. CTP directly converts digital files into plates, enabling the printing press to be prepared for printing more quickly, resulting in shorter production cycles and faster turnaround times. This provides a significant advantage for printing projects with tight delivery deadlines.

-

Cost Efficiency:

Computer to Plate (CTP) reduces material costs and waste by eliminating the need for film and related chemicals used in traditional processes. In the traditional film method, costs are incurred for film, chemicals, exposure equipment, and washing equipment. CTP removes these steps and, by using digital files, reduces reliance on physical film, thus lowering overall production costs, particularly in large-volume production.

-

Environmental Benefits:

Computer to Plate (CTP) reduces the use and handling of chemicals, promoting a more environmentally friendly printing process. Since CTP directly transfers images onto the plate, it eliminates the chemical developing steps, thereby reducing the generation of chemical waste and contributing to a more sustainable production process.

Types of Computer to Plate CTP Systems

| CTP System Type | Image | Features |

| Thermal CTP Systems |

|

Thermal CTP Systems use infrared lasers to expose thermal plates, providing high resolution and clear image reproduction, making them ideal for high-quality commercial printing. Thermal plates are less sensitive to ambient light, allowing for safer handling. |

| Violet CTP Systems |

|

Violet CTP Systems use violet laser diodes and offer a more cost-effective solution suitable for a variety of printing needs, including newspaper printing. Since violet plates are sensitive to visible light, they must be handled under specialized safety lighting to avoid exposure. |

| UV CTP Systems |

|

UV CTP Systems use ultraviolet light sources to expose the plate, providing a faster imaging process and compatibility with various types of plates. Although these systems are less common, they offer significant advantages in certain specific printing applications. |

Computer to Plate CTP Process Workflow

Prepress Preparation: Use design software to finalize digital files (PDF, AI, etc.), ensuring correct color profiles, resolution (2400-3600 dpi), and trapping.

- Raster Image Processing (RIP): The software converts the file into a raster bitmap, determining the dot pattern for ink application.

- Plate Imaging: The CTP machine uses a laser (thermal, ultraviolet, or visible light) to etch the image onto the plate, controlled by the RIP data.

- Plate Development: The exposed plate undergoes chemical processing (except for non-processing types), removing the unexposed coating. Thermal plates may require baking to ensure durability.

- Quality Control: Automated systems check for defects and alignment accuracy.

- Printing Press Setup: The plate is installed on a lithographic press, flexographic press, or gravure press for printing.

Key Components of Computer to Plate CTP

CTP Machine: Uses a laser diode for precise imaging. Types include:

- Internal Drum: The plate is mounted inside the drum; high precision, suitable for high-resolution jobs.

- External Drum: The plate is wrapped around a rotating drum; faster speeds, ideal for high-volume printing.

- Flatbed: The plate lies flat; suitable for various plate sizes.

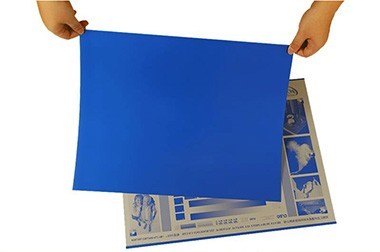

- Plates: Made of aluminum, polyester, or polymer bases with photosensitive coatings. Types include:

- Thermal: Infrared laser; suitable for long runs.

- Visible Light: Blue/green laser; suitable for medium-volume printing, cost-effective.

- Ultraviolet: Low-energy laser; a balance of cost and quality.

- Plate Processor: Develops the plate chemically or thermally (plates requiring no processing skip this step).

- Software: RIP and workflow tools manage color, imposition, and output settings.

Advantages of Computer to Plate CTP Over Traditional Methods

- Quality: Higher resolution without compromising the quality of the film.

- Speed: Skips the film step, accelerating turnaround time.

- Cost-effectiveness: Reduces costs for film, labor, and storage.

- Sustainability: Minimizes chemical use and waste, especially with no-process plates.

- Consistency: Improves registration and color accuracy.

Computer to Plate CTP Technologies

| CTP Technology | Description |

| Thermal CTP | Thermal CTP technology uses infrared lasers to expose light-sensitive plates, heating them locally to transfer the image. Due to the use of thermally sensitive materials, Thermal CTP plates maintain extremely high durability under high-temperature conditions, making them ideal for long-term, high-volume printing jobs such as packaging printing. Compared to other traditional technologies, Thermal CTP provides more stable printing quality, capable of handling continuous high-load production while ensuring consistent and accurate print quality during long operations. |

| Violet CTP | Violet CTP is characterized by its low cost and ease of production. Compared to more expensive plate materials, the violet laser in Violet CTP makes its plates highly competitive in the commercial printing sector, especially for short-run or medium-volume production. |

| Processless Plates | Processless Plates technology eliminates the need for traditional chemical developing processes. After exposure, the plate can be directly used for printing without requiring additional chemical treatments or rinsing. This technology reduces reliance on chemicals, significantly lowering environmental impact. |

Plate Types

- Negative-Working: Exposed areas become ink-receptive (common in thermal CTP).

- Positive-Working: Unexposed areas accept ink (used in violet CTP).

- Polyester Plates: Affordable for short runs; common in small offset presses.

Computer to Plate CTP Applications

- Commercial Printing: Brochures, magazines.

- Packaging: Corrugated board, flexible packaging.

- Newspapers: High-speed production of daily newspapers.

Considerations

While CTP offers many benefits, it requires a fully digital workflow. This means that all printing materials and layouts must be in digital format and require precise preparation of digital files. Additionally, if the plate is damaged or needs modification after exposure, a new plate must be created, as partial corrections are not possible.

Computer to Plate technology has revolutionized the printing industry by simplifying the prepress workflow, improving print quality, and offering environmental benefits. Its adoption has become the standard for modern printing businesses, catering to a wide range of applications from commercial printing to packaging.

Users viewing this material also viewed the following

Further reading: computer to plate machinecomputer to platecomputer to plate ctpcomputer to plate printingcomputer to plate systemsctp computerctp computer to platectp computer to plate machine