Aluminium Printing Plates

Jul. 25, 2025

What Are Aluminum Printing Plates?

Aluminum printing plates are a key material used in the printing industry. They refer to printing image carriers made from aluminum sheets as the base material, which undergo special surface treatments and are coated with photosensitive layers.

Aluminum printing plates—typically used in offset printing—are high-quality processed aluminum sheets that carry printed images through a photosensitive coating. These plates are the foundation of offset printing and serve as the medium for image data transfer in large-scale print production. Aluminum printing plates mainly include two categories:

- CTP (Computer-to-Plate) plates—use laser etching technology to directly engrave image data

- PS (Presensitized) plates—require film exposure and chemical development

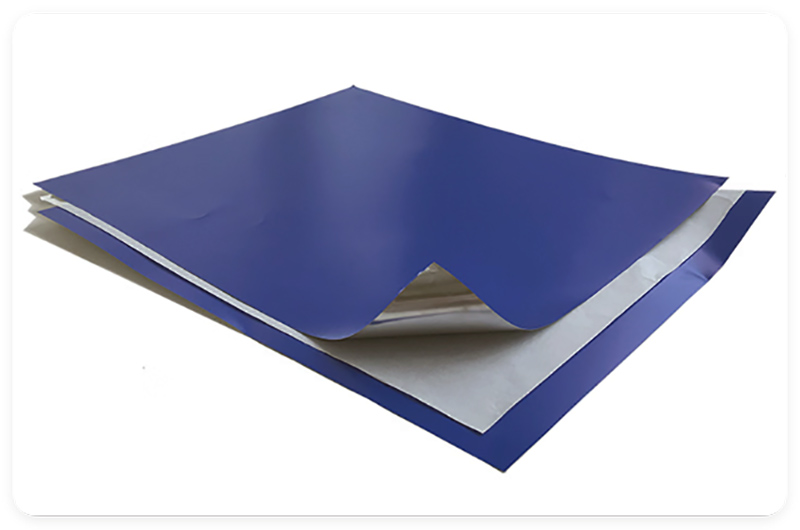

These plates are usually composed of multiple layers, including a pure aluminum base, a mechanically or electrochemically grained (roughened) layer to enhance durability, an anodized coating, and a photosensitive emulsion that determines the printed image.

The base material of aluminum printing plates is typically made from ultra-pure aluminum alloys (such as grades 1050, 1060, 1070, etc.). These aluminum alloys are lightweight, have high strength, moderate wear resistance, and excellent corrosion resistance and chemical stability. After being coated with diazo resin or photopolymer photosensitive layers, the aluminum plates offer high resolution (capable of reproducing fine dots) and excellent dimensional stability over large areas. Due to the good hydrophilicity of the aluminum plate surface, its printing lifespan is relatively long. Standard plates can typically achieve tens of thousands of impressions, while long-life plates (such as violet laser CTP plates) can exceed 500,000 impressions, making them suitable for high-volume, high-precision commercial printing, newspapers, books, and other applications.

Common Specifications and Sizes of Aluminium Printing Plates

The thickness of aluminum printing plates generally ranges from 0.15 to 0.30 millimeters. Common sizes vary and are measured in millimeters. Depending on equipment specifications and printing requirements, various sizes from quarter to full format are produced.

Common specifications and sizes

Thickness:

Standard: 0.12 mm, 0.14 mm (0.15 mm), 0.23 mm (0.25 mm), 0.27 mm (0.30 mm)

Non-standard: 0.40 mm

Width/Length:

Typical width: 650–1600 mm

Haomei Aluminium Printing Plates

| Description | Size | Thickness |

| Process Less Plates | 335mm x 485mm | 0.12mm |

| Procesless Thermal CTP Plate | 510mm x 400mm | 0.15mm |

| Positive Thermal Plates | 650mm x 450mm | 0.15mm |

| Offset Printing Plates | 400mm x 514mm | 0.2mm |

| Offset Printing Plates | 310mm x 514mm | 0.2mm |

| Offset Printing Plates | 388mm x 495mm | 0.2mm |

| Offset Printing Plates | 469mm x 572mm | 0.2mm |

| Offset Printing Plates | 514mm x 388mm | 0.2mm |

| Offset Printing Plates | 308mm x 495mm | 0.2mm |

| Double Coating Layer (positive CTCP plate) | 745mm x 605mm | 0.2mm |

| CTCP Plates | 800mm x 1030mm | 0.28mm |

| CTCP Plates | 800mm x 1030mm | 0.3mm |

| CTCP Plates | 745mm x 605mm | 0.3mm |

| CTCP Plates | 1055 x 811mm | 0.3mm |

| CTCP Plates | 766mm x 605mm | 0.3mm |

| CTP Thermal Double Layer | 785mm x 1030mm | 0.3mm |

| CTP Thermal Double Layer | 790mm x 565mm | 0.3mm |

| CTP Thermal Double Layer | 790mm x 595mm | 0.3mm |

| Procesless Thermal CTP Plate | 650mm x 550mm | 0.3mm |

| UV CTP Plates | 1030mm x 785mm | 0.3mm |

| UV CTP Plates | 1050mm x 795mm | 0.3mm |

| Conventional CTP Plates | 740mm x 605mm | 0.3mm |

| Thermal Offset Plates (positive) | 750mm x 840mm | 0.3mm |

| CTP Plates Thermal Single Layer | 13 3/16" x 19 3/8" | 6ml |

| CTP Plates Thermal Double Layer | 13 3/16" x 19 3/8" | 6ml |

| CTP Plate | 104.5mm x 80.5mm | Customized |

| CTP Plate | 800mm x 600mm | 0.3mm |

| CTP Plate | 910mm x 665mm | 0.3mm |

| CTP Plate | 920mm x 760mm | 0.3mm |

| CTP Plate | 1030mm x 770mm | 0.3mm |

| CTP Plate | 1030mm x 790mm | 0.3mm |

| CTP Plate | 1030mm x 838mm | 0.3mm |

Features of Aluminum Printing Plates

- High resolution and dot reproduction: Capable of reproducing 1–99% tones at resolutions up to 250–450 LPI.

- Durable and stable: Aluminum plates offer high strength, corrosion resistance, and consistent flatness, making them ideal for multiple print runs.

- Environmentally friendly: CTP plates eliminate the need for film and chemical processing, reducing pollution. Recyclable aluminum material enhances sustainability.

- Thermal conductivity: Rapid heat dissipation ensures process stability.

Types of Aluminum Printing Plates

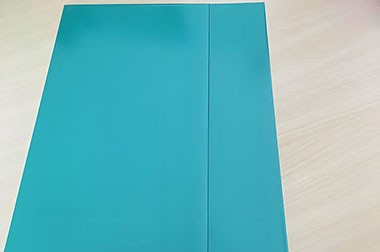

PS (Presensitized) Plates: Traditional photosensitive aluminum plates; available in positive and negative types.

CTP (Computer-to-Plate):

- Thermal CTP: Uses infrared lasers (~830nm). Offers high precision and long-run printing (100K–500K), daylight-safe.

- UV/Violet CTP: Faster imaging speed (400nm), operable under yellow light.

- Process-free/chemistry-free: No chemical treatment required, environmentally friendly.

Thermal CTP Plate

Thermal CTP plates use infrared thermal lasers (wavelength around 830nm) for imaging. The laser beam transfers thermal energy directly to the photosensitive coating, rapidly melting and curing the image area. Thermal plates offer fast imaging speed and high sensitivity, enabling precise image and text transfer. They are ideal for high-quality commercial printing such as brochures, magazines, and catalogs. Their advantages include stable imaging, strong adaptability to environmental temperature and humidity, and no need for preheating—making them highly favored by printing enterprises.

Violet Laser CTP Plate

Violet CTP plates are imaged using 405nm violet laser exposure, characterized by fast plate-making speed and high stability. These plates typically use water-washable positive (image-on-top) coatings with high photosensitivity and are compatible with both conventional and UV-curable inks. Violet laser plates are commonly used for high-volume and high-speed printing, such as newspaper printing. Thanks to their fast imaging speed, they meet the tight plate-making timelines of the news industry. They also offer long print runs, making them cost-effective for extended use.

UV-CTP Plate (UV Plate)

The UV-CTP plate (UV plate) is sensitized using ultraviolet light sources. Its coating contains photopolymerization initiators and other components. After imaging, UV-CTP plates can be washed with tap water or even go directly to the press without chemical development, eliminating the chemical processing step. This type of plate offers high sensitivity and excellent dot reproduction. Tests have shown it to have a high print run life. UV-CTP plates are suitable for printing environments with high environmental and efficiency requirements and perform especially well on UV-curable printing presses.

Process-free CTP Plate (Chemistry-free Plate)

Process-free CTP plates (chemistry-free plates) are specially formulated so that after exposure they can be printed directly or with just simple water rinsing. This provides an environmental advantage. Such plates are ideal for enterprises subject to strict environmental regulations or those requiring fast plate-making. They help save on chemical agents and reduce wastewater emissions.

Silver Halide CTP (Photopolymer Type) Plate

Silver Halide CTP (Photopolymer Type) Plate

Silver halide CTP (photopolymer type) plates use silver halide photosensitive materials and form images through chemical development. These plates deliver exceptionally high imaging quality, with outstanding resolution and detail reproduction. They are suitable for high-end art reproduction and fine packaging printing. However, the development process is relatively complex, with higher production costs and greater chemical consumption.

Advantages of Aluminum Printing Plates

- Excellent Image Quality: High-purity aluminum alloys (such as 1050, 1060, 1070, 1100) ensure superior resolution and dot sharpness for fine offset printing.

- Durable and Long-lasting: The anodized and grained surface provides wear resistance, chemical resistance, and abrasion resistance, enabling high print runs (up to about 500,000 impressions).

- Environmentally Friendly: Aluminum is infinitely recyclable. Modern CTP workflows significantly reduce the use of chemicals and water, supporting sustainability.

| Pros | Cons |

| High resolution and sharp dot reproduction | Surface scratches from handling can degrade quality |

| Long-lasting, re-usable across many prints | Higher initial cost vs. polyester or film plates, but cheaper long-term |

| Recyclable and eco-friendly | Primarily viable in offset printing (not suitable for other methods) |

| Lightweight and easy to handle | Requires careful surface handling to avoid damage |

Common Applications of Aluminum Printing Plates

- Large-volume commercial offset printing: Suitable for magazines, product catalogs, brochures

- Packaging: Labels, printed cartons, flexible packaging

- Art and educational printmaking: Used for drypoint, etching, and small anodized artistic plates in print studios (e.g., 0.9 mm anodized aluminum sketch plates)

Comparison Between Aluminum Printing Plates and Other Plate Materials

- Compared to Flexographic Plates (Photopolymer Flexo Plates): Flexographic plates, usually made from photosensitive resin, have a soft base material, making them suitable for printing on flexible substrates such as plastic films, metal foils, and corrugated boards. The surface of a flexo plate is relief-style and has a very high durability, often capable of printing up to millions of impressions. Plate-making and printing efficiency is high, ideal for large-volume color packaging and label printing. However, flexo plates have relatively weaker color registration accuracy and dot reproduction ability, with typically lower screen rulings (≤175 LPI), resulting in less sharp line work than aluminum plates. Aluminum offset plates, by contrast, use planographic printing with high resolution, excellent ink adaptability (achieving high-fidelity multicolor printing through water-ink balance), and better registration accuracy—making them suitable for high-precision print products. The downside is that aluminum plates are harder and not suitable for elastic substrates, and their print run life is generally lower than that of premium flexo plates.

- Compared to Traditional Film-Based Plate-Making (PS Plates): Traditional offset printing uses silver halide PS plates or positive-working PS plates, which require exposure through film (photolithography), involving multiple steps and prone to dimensional inaccuracies. Aluminum CTP plate-making eliminates the film output process, imaging directly with laser, significantly shortening the plate-making time and improving image fidelity. Additionally, PS plates usually require strong alkaline developer solutions, which pose greater environmental pollution risks. CTP plates can use low-chemical or chemistry-free systems, making them more eco-friendly. However, CTP equipment and plate materials have higher initial costs. Traditional film-based plates require less advanced equipment, making them suitable for small-batch or budget-constrained print jobs.

- Compared to Other Printing Plate Types: For example, gravure printing plates (copper plates) or screen printing plates, aluminum offset plates offer superior fine-detail reproduction and CMYK color registration. Gravure plates are better suited for ultra-large-volume printing and special inks (e.g., for flexible packaging), while screen printing is ideal for special substrates and processes. Overall, aluminum printing plates dominate the commercial offset printing market. Their water-ink balance principle enables high-quality print results, while other plate types have their own advantages and should be selected based on the specific requirements of the printed product.

Advantages vs. Other Plate Materials

| Feature | Aluminum Plates | Phenolic Plates | Polyester Plates |

| Durability | Very high; for long-run jobs | High-temp tolerant, but lower precision | Good wear resistance; shorter runs |

| Precision | Excellent; up to ~450 LPI dot reproduction | Lower resolution | Moderate precision |

| Stability & handling | Flat, chemically resistant; ideal for high volumes | More heat resistant | Less durable in long runs |

| Cost-efficiency | Higher upfront cost but low per-sheet cost over long runs | Lower cost but less durable | Cheapest, for short runs |

| Eco-friendliness | Recyclable and CTP cuts chemistry usage | Less recyclable | Plastic-based; minor ecological footprint |

Choosing the Right CTP Plate

- If you are using a CTP workflow and prioritize efficiency, quality, and reduced chemical usage, choose thermal or UV-CTP aluminum plates.

- For traditional exposure workflows or budget-conscious long-run printing jobs, choose PS plates with photosensitive coating.

- Select the appropriate plate thickness and aluminum alloy based on equipment specifications and printing volume requirements.

- Ensure proper handling and storage to avoid scratches and maintain surface integrity.

Further reading: ctp plates for offset printingctp printingcomputer to plate printingctcp printing platesctp machine for printingctp offset printingctp offset printing platesctp printing plateoffset printing ctp plateoffset printing plate making machineplatesetter printing