1060 h18 PS CTP aluminum plate substrate

Mar. 06, 2025

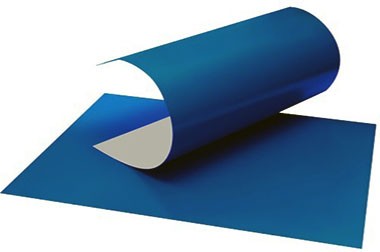

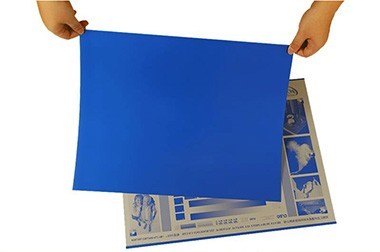

Printing plate making is one of the processes before printing. The printing plate base includes aluminum plate, aniline plate, etc. At present, aluminum-based plates are used more often. The commonly used printing PS CTP plate aluminum plate base material is generally 1 series 1060 H18 aluminum plate alloy.

Among aluminum-based printing plates, 1-series aluminum alloys have become the mainstream choice due to their high purity and excellent performance. 1060 aluminum plate is the most common 1 series aluminum alloy, containing up to 99.6% aluminum, and belongs to the category of pure aluminum.

PS CTP aluminum plate base material thicknesses are available in three types: 0.3mm, 0.24mm, and 0.1mm. Most are made of 1060 aluminum coils and 1070 aluminum alloys with a thickness of 0.2 to 0.28mm. A few are produced using 3003 aluminum plates.

1060 h18 PS CTP aluminum plate substrate characteristics

- Low density: helps reduce the weight of the finished product, making it easier to handle and use.

- Easy to process: It has good ductility and formability, and is suitable for stamping, stretching and other processes.

- Corrosion resistance: The natural aluminum oxide layer gives it better corrosion resistance and extends its service life.

- Good electrical/thermal conductivity: High-purity aluminum has excellent electrical and thermal conductivity, which helps improve the conduction efficiency of electrical and thermal energy during the printing process.

- Good surface treatment: It is easy to carry out surface treatment such as anodization and electroplating to improve the wear resistance of the printing plate and the adhesion of the photosensitive layer.

1060 h18 PS CTP aluminum plate substrate applications

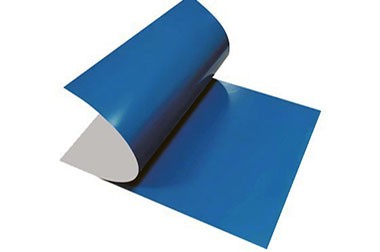

1060 aluminum plates are widely used in offset printing plates such as positive PS plates, thermal CTP plates, photosensitive CTP plates, and UV-CTP plates. The main difference between the PS version and the CTP version is that the former is made through traditional plate making technology, while the latter is made using computer-to-plate technology (CTP). These plates have different application scenarios and technical requirements in the printing industry.

Users viewing this material also viewed the following

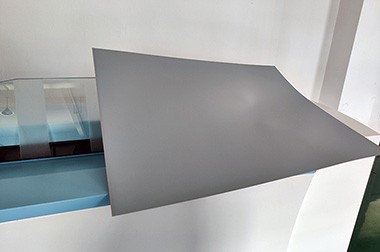

1060 H18 aluminum plate base surface requirements

- The basic requirements for the surface of the aluminum plate base are clean, smooth, and free of defects such as cracks, corrosion pits, spots, pores, scratches, folds, marks, peeling, pine branches, oil stains and other defects.

- The surface is free of defects such as sticky plates, scratches, and non-metallic skin.

- Slight color differences, bright stripes, etc. are not allowed.

- There should be no bulges, wrinkles, etc.

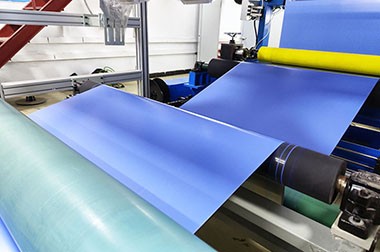

1060 H18 PS CTP aluminum plate base production process

- 1. Raw material selection: Use high-purity 1060 aluminum coil as the base material.

- 2. Hot rolling and cold rolling: Through a series of hot rolling and cold rolling processes, the aluminum coil is processed into aluminum plates of the required thickness.

- 3. Surface treatment: Treat the surface of the aluminum plate, including cleaning, chemical oxidation, electrolytic oxidation and other steps to enhance its surface properties.

- 4. Coating photosensitive material: Coating photosensitive material on the surface of the treated aluminum plate to form a PS plate or CTP plate.

Since 1060 H18 aluminum plate has many advantages such as low density, easy processing, corrosion resistance, good electrical/thermal conductivity and good surface treatment, it meets the processing, use and performance needs of printing plates. In addition, the production process of 1060 aluminum plates is relatively simple, the technology is mature, and the cost is low, so it has strong competitiveness in the market and is widely used.

Although 1060 aluminum sheets dominate the market, in some specific applications, 1070 aluminum alloy coils and 3003 aluminum sheets are also used. 1070 aluminum alloy contains higher aluminum content, has a purity close to 99.7%, and its properties are similar to 1060 aluminum. 3003 aluminum plate is an alloy with a small amount of manganese added. It has better strength and corrosion resistance and can be used in situations where higher strength is required.

In short, the wide application of 1060 aluminum plate in printing plate substrates has benefited from its excellent material properties and economy, making it an indispensable and important material in the printing industry.

Further reading: ctp platectp machinectp plate making machinecomputer to plate machinecomputer to platecomputer to plate ctpctp printingcomputer to plate printingcomputer to plate systemsctcp plate making machinectcp printing platesctp computerctp computer to platectp computer to plate machinectp machine for printingctp offset printingctp offset printing platesctp printing plateoffset printing ctp plateoffset printing plate making machineplatesetter printing