1050 H18 Aluminum Coil for PS CTP Plate

Mar. 06, 2025

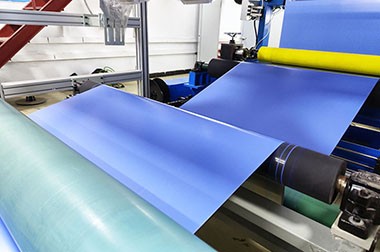

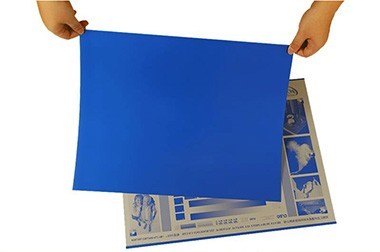

1050 H18 Aluminum Coil is a widely used material in the printing industry, particularly for PS (presensitized) CTP (computer-to-plate) plates.

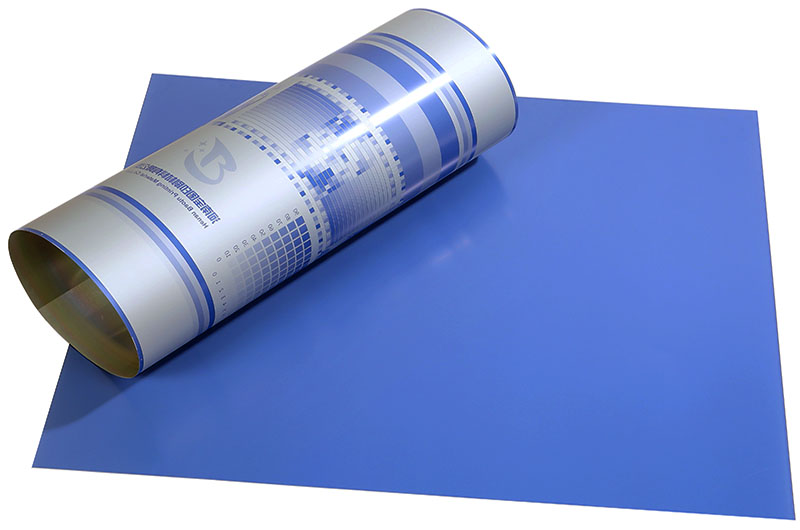

PS CTP board substrate is usually made of aluminum, alloy grade 1050, in H condition. There are three types: H18, H22 and H26. They are all packed in rolls and supported by wooden pallets. The thickness tolerance is approximately 0.27mm, and the surface roughness must not be greater than 0.30 microns.

1050 H18 Aluminum Coil for PS Plate

PS plates or lithographic plates are used in the lithographic printing process in the printing industry. 1050 H18 aluminum coil is an ideal material for PS plates for the following reasons:

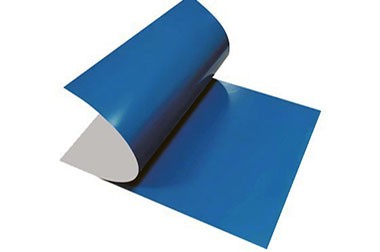

- 1. High purity: ensuring a smooth surface, which is crucial for uniform coating of the photosensitive layer.

- 2. Surface quality: Provides excellent flatness and surface finish, which is crucial for high-quality printing.

- 3. Strength and durability: H18 tempering provides the necessary hardness and strength to ensure longevity and resistance to deformation during the printing process.

- 4. Corrosion resistance: It is crucial for the service life and durability of the board in various environmental conditions.

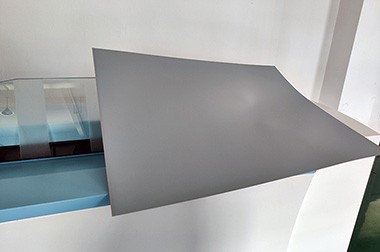

1050 H18 Aluminum Coil for CTP Plate

CTP plates are also used in the printing industry but are designed for direct digital imaging processes without the need for an intermediate film. 1050 H18 aluminum coil is suitable for CTP plates due to its following characteristics:

- 1. High Purity: Ensures excellent imaging quality and uniformity, which are crucial for precise digital printing processes.

- 2. Dimensional stability: H18 tempering ensures that the printing plate maintains its shape and size under the pressure of high-speed printing.

- 3. Electrical conductivity: Good thermal and electrical conductivity helps to process sheets quickly and efficiently, helping to save energy and shorten production time.

- 4. Thermal conductivity: In the laser imaging process, effective heat dissipation is crucial.

- 5. Surface finish: High-quality surface finish ensures accurate and consistent image reproduction.

1050 H18 aluminum coil is the best choice for the printing industry to manufacture PS and CTP plates. Its combination of high purity, excellent mechanical properties and excellent surface quality make it a versatile and reliable material suitable for high-quality printing applications.

1050 H18 Aluminum Coil for PS CTP Plate Mechanical Properties

| Product | 1050 H18 |

| Tensile Strength | 155-185 |

| Elongation at Break | ≥1 |

1050 H18 Aluminum Coil for PS CTP Plate Chemical Composition

| Element | Composition (%) |

| Aluminum (Al) | 99.50 min |

| Silicon (Si) | 0.25 max |

| Iron (Fe) | 0.40 max |

| Copper (Cu) | 0.05 max |

| Manganese (Mn) | 0.05 max |

| Magnesium (Mg) | 0.05 max |

| Zinc (Zn) | 0.05 max |

| Titanium (Ti) | 0.03 max |

| Other elements (each) | 0.03 max |

| Other elements (total) | 0.10 max |

Benefits of using 1050 H18 aluminum coil for PS CTP plate

- 1. Cost Effectiveness: The relatively low cost of 1050 aluminum compared to other alloys makes it an economical choice for mass production.

- 2. Processability: Despite its H18 hardness status, 1050 aluminum can still be easily processed and coated, which is advantageous during the manufacturing process of PS CTP plates.

- 3. Environmentally friendly: Aluminum is a recyclable material, and using 1050 H18 aluminum contributes to sustainable practices in the printing industry.

1050 H18 aluminum coil meets the specific requirements of PS CTP plate

- (1) The gap between the unrolled surface of the 1050 aluminum coil and the flat surface shall not be greater than 1mm, and the wave number per meter of the unrolled surface shall not be greater than 3.

- (2) The length of edge bends shall not be greater than 1mm per meter.

- (3) The 1050 aluminum coil should be compact and the end faces should be neat and free of cracks and burrs.

Haomei Aluminum ensures that 1050 H18 aluminum coils can maintain high-quality surface and edge conditions during the production process of PS CTP panels, reducing problems during processing and improving the performance and reliability of the final product. Haomei Aluminum's strict standards ensure that the physical properties of 1050 h18 aluminum coils meet the high requirements of the printing industry, ensuring the excellent performance of CTP boards in practical applications.

Users viewing this material also viewed the following

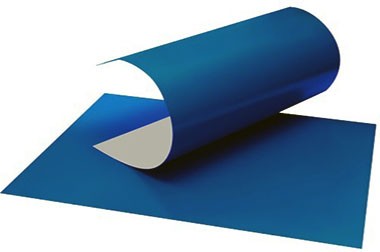

PS CTP plate manufacturing process of 1050 H18 aluminum coil

- 1. Cleaning and roughening: The 1050 aluminum coil undergoes a cleaning process to remove impurities, and then is roughened to enhance the adhesion of the photosensitive layer.

- 2. Coating: Apply photosensitive coating on the prepared 1050 aluminum surface. This layer is sensitive to laser light and is used to create the image on the printing plate.

- 3. Imaging and developing: Expose the coated plate to a laser to form the desired image. After exposure, the plate is developed to fix the image and prepare it for printing.

- 4. Finishing: The finished boards are cut to size and quality checked, then packaged and shipped to the printing facility.

1050 H18 aluminum coil is an ideal material for producing PS CTP plates due to its excellent physical and chemical properties, cost-effectiveness, and suitability for high-precision applications. Its widespread use in the printing industry highlights its importance in ensuring high quality and efficient printing processes.

Further reading: ctp platectp machinectp plate making machinecomputer to plate machinecomputer to platecomputer to plate ctpctcp platectp plates for offset printingctp printingcomputer to plate printingcomputer to plate systemsctcp plate making machinectcp printing platesctp computerctp computer to platectp computer to plate machinectp machine for printingctp offset printingplatesetter printingoffset printing plate making machineplate ctpoffset printing ctp plateoffset ctpctp printing platectp plate machinectp offset printing platesthermal ctp