CTP plate base uses 1050A 1060 aluminum plate

Mar. 06, 2025

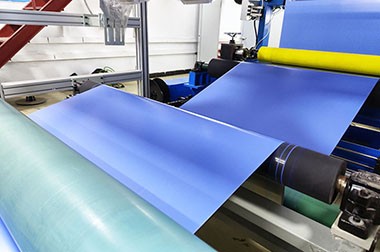

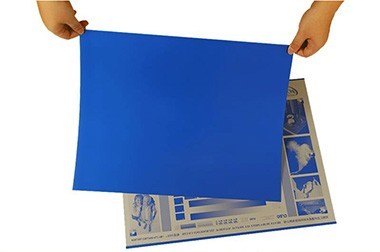

CTP (Computer-to-Plate) technology in the printing industry involves transferring a digital image directly onto a printing plate, now usually aluminum, which is then used for offset printing. The aluminum base of these plates plays a vital role in the quality and durability of the printing process.

Users viewing this material also viewed the following

CTP plate base generally uses 1 series pure aluminum plate. 1050 aluminum plate and 1060 aluminum plate are more commonly used. They have the advantages of high printing quality, strong printing durability, environmental friendliness, cleanliness and reasonable cost.

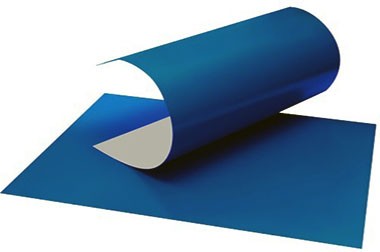

1050 aluminum plate and 1060 aluminum plate, as CTP plate base materials, have good physical and chemical properties, ensuring high resolution and clarity of images during the printing process. After special treatment on the surface of the pure aluminum plate, a uniform and fine oxide layer can be formed. This layer can not only enhance the corrosion resistance of the plate base, but also improve the adhesion and reproducibility of the image, thereby ensuring high-quality output of printed matter.

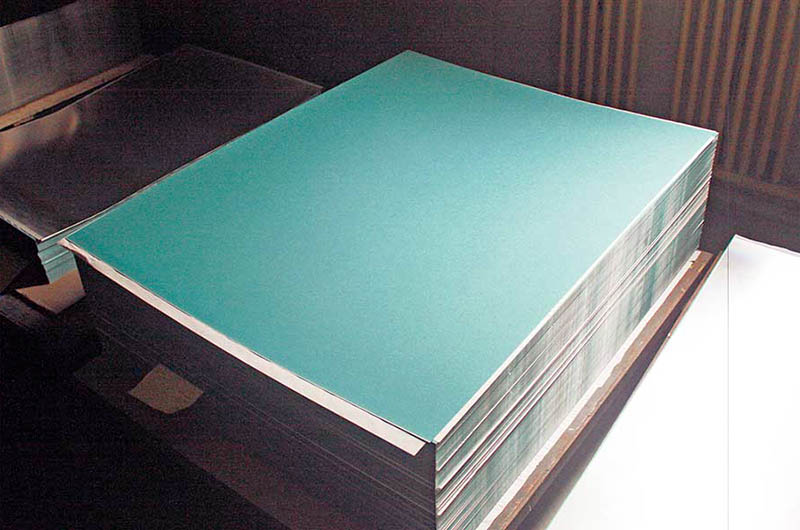

1050 aluminum plate and 1060 aluminum plate have good fatigue resistance and mechanical strength due to their high purity and low impurities. This makes them less likely to deform during high-frequency, high-intensity printing processes, maintain good printing results for a long time, and extend the service life of the plate.

CTP plate base aluminum material specifications

- Typical alloys: 1050A, 1050, 1060

- Material status: H18

- Thickness (mm): 0.13-0.40

- Width (mm): 650-1420

- Length (mm): C (according to customer requirements)

1050 1060 Aluminum Sheet Plate CTP plate base performance parameters

| Alloy | 1050A | 1060 |

| Tensile strength (normal temperature) | 185~215MPA | 200~230MPA |

| Tensile strength (baking plate) | 125~140MPA | 125~140MPA |

| Elongation after break | >1% | >1% |

- 1050A: Sufficient strength for many general applications, but slightly lower than 1060.

- 1060: Slightly better mechanical strength and formability.

1050A 1060 aluminum plate for CTP plate base chemical composition

| Element | 1050A Aluminum | 1060 Aluminum |

| Aluminum (Al) | 99.5% min | 99.6% min |

| Silicon (Si) | 0.25% max | 0.25% max |

| Iron (Fe) | 0.40% max | 0.35% max |

| Copper (Cu) | 0.05% max | 0.05% max |

| Manganese (Mn) | 0.05% max | 0.03% max |

| Magnesium (Mg) | 0.05% max | 0.03% max |

| Zinc (Zn) | 0.05% max | 0.05% max |

| Titanium (Ti) | 0.03% max | 0.03% max |

| Other elements | 0.03% each max | 0.03% each max |

| Total other elements | 0.03% max | 0.03% max |

Notes:

Aluminum (Al): Both alloys have high aluminum content, with 1060 having a slightly higher purity than 1050A.

Impurities and Alloying Elements: Both alloys contain similar small amounts of other elements such as silicon, iron, copper, manganese, magnesium, zinc, and titanium, with slight variations in their maximum allowable percentages.

This table summarizes the slight differences in composition, reflecting the slightly higher purity of 1060 aluminum compared to 1050A. This higher purity gives 1060 marginally better mechanical properties and formability.

How to choose 1050A and 1060 aluminum plates for CTP base

1. Performance requirements

If your application requires slightly better mechanical properties and formability, choose 1060 aluminum.

For applications where standard properties are sufficient, 1050A aluminum is a cost-effective choice.

2. Cost considerations

1050A aluminum is generally more economical due to its slightly lower purity.

1060 aluminum may be slightly more expensive but can provide better performance for specific requirements.

3. Specific application requirements

For general CTP base, excellent corrosion resistance and good conductivity are enough, and 1050A is usually enough.

For more demanding applications, where every extra bit of strength and formability counts, 1060 would be the better choice.

Both 1050A and 1060 aluminum plates are suitable for use as CTP plates and have excellent corrosion resistance, ductility and conductivity. The choice between them comes down to your application's specific performance requirements and cost considerations. If slightly better mechanical properties and formability are required, 1060 is the first choice. For most standard applications, the 1050A provides a cost-effective solution.

Compared with other metal materials, the price of 1 series pure aluminum plates is relatively low, with mature production technology and complete supply chain. Therefore, using 1050 aluminum plate and 1060 aluminum plate as CTP plate base material has a high cost performance. They not only provide high-quality printing results, but also effectively control production costs, making them an economical choice in the printing industry.

The application of 1050 aluminum plate and 1060 aluminum plate in CTP plate base has become the preferred material in the printing industry due to its superior performance and reasonable cost. Their use not only improves the quality and durability of printed matter, but also meets environmental protection and hygiene requirements, providing reliable material support for the development of the modern printing industry.

Further reading: ctp platectp machinectp plate making machinecomputer to plate ctpctp printingctp computerctp computer to platectp computer to plate machinectp machine for printingctp plate machinectp printing plateplate ctp