What is thermal CTP plates?

Jul. 24, 2025

Thermal CTP (Computer-to-Plate) plates are a type of printing plate used in the prepress stage of offset printing, where digital files are directly transferred to the printing plate without the need for traditional film. These plates use thermal energy to create an image on the plate, which is then exposed by a laser to produce the image area that will accept ink during the printing process.

Thermal CTP plates are printing plates used in the printing industry, where digital images are transferred directly to the plate using thermal imaging technology. CTP stands for "Computer-to-Plate," which refers to the process of creating high-quality printing plates using digital files (such as those created by computer software) without the traditional photographic process.

Haomei Aluminum Thermal CTP Plates

| Product | Image | Description |

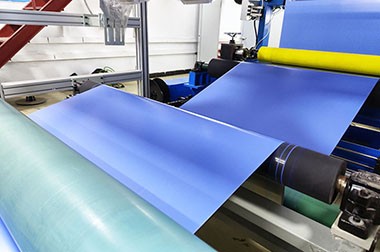

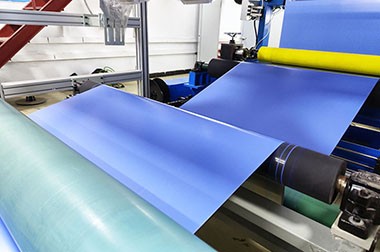

| Thermal CTP plate (Single-layer) |

|

Single-layer thermal CTP plates are capable of producing high-resolution images, making them suitable for fine and high-quality printing applications. |

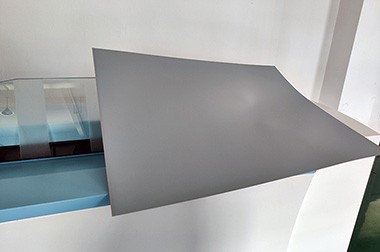

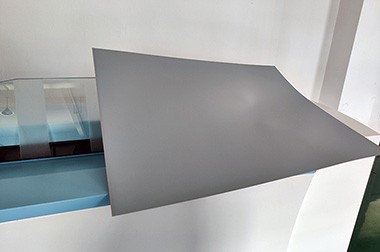

| Thermal CTP Plate (Double Layer) |

|

Double Layer Thermal CTP Plate is made of two layers, the top layer is photosensitive material and the bottom layer is heat-resistant material. It is widely used in the printing industry due to its excellent image reproduction quality and efficiency. |

| Thermal CTP Plate(Process-less) |

|

The process-free thermal CTP plate is a thermal printing plate that does not require chemical processing or any post-exposure steps after imaging, making it the simplest method of plate making. |

| Positive Thermal CTP Plate |

|

Positive Thermal CTP Plate is a type of digital plate-making technology used in the printing industry, widely applied in printing production, especially under the demand for high-quality printing and rapid production. |

Characteristics of Thermal CTP Plates

- High Sensitivity: Thermal CTP plates have high sensitivity to light, meaning they can effectively respond to laser exposure. The thermal treatment allows for precise control of exposure, producing clear, high-quality images.

- Hydrophilic Properties: These plates exhibit good hydrophilic properties (water-absorbing ability) in the non-image areas. The hydrophilic surface ensures that the non-printing areas of the plate retain moisture, preventing ink from adhering to these areas, which is crucial for maintaining proper water-ink balance during printing.

- Water-Ink Balance: Thermal CTP plates maintain a good balance between water and ink, which is essential for achieving clear, sharp, and accurate printing. A good water-ink balance ensures better print quality, especially in commercial and newspaper printing.

- Long Print Run: These plates have a longer print run, meaning they can be used for a longer time before needing replacement. This characteristic makes them particularly valuable for large-volume commercial printing applications.

- Market Compatibility: Thermal CTP plates can meet various market demands, including traditional wet plates and alcohol-based wet plates. This versatility ensures that they can be used for different types of printing applications.

- High-Resolution Imaging: With high-resolution imaging, thermal CTP plates can reproduce sharp edges and fine dots, making them ideal for high-quality printing. These plates provide rich tonal reproduction, ensuring clear and detailed images with accurate colors.

- Process Flexibility: Thermal CTP plates have a wide development tolerance, allowing them to accommodate various developers and different concentrations. This flexibility makes the production process smoother and reduces the likelihood of errors or inconsistencies.

- Durability: The aluminum-based materials used in these plates employ composite molybdenum structural technology, enhancing their ability to produce high-quality microdots, even with varying ink densities (microdot reproduction ranges from 1% to 99%). This contributes to the durability and reliability of the plates in high-speed production.

- High Resolution: The plates offer very high resolution, making them suitable for fine printing applications, such as publications with detailed images or graphics. The thermal imaging process ensures precise capture of small, complex details.

- Excellent Imaging Performance: The thermal imaging process allows for the creation of precise and fine images, which is crucial for modern printing production. The plates can produce high-quality images with fine details, something that older traditional technologies often struggle to achieve.

- Environmental Benefits: Thermal CTP plates are environmentally friendly, as they eliminate the need for traditional photographic processes (such as film development and chemical treatments), reducing chemical waste and simplifying the production process.

- Multi-Particle Structure: The multi-particle structure of the plates enhances their water retention ability, ensuring optimal water-ink balance. This structure also helps maintain consistent print quality during long print runs.

There are two main types of Thermal CTP Plates

Thermal CTP plates are materials used for printing plate-making, with the two common types being thermal-melt and thermal-crosslinking.

- Thermal-Melt CTP Plates: These plates are exposed to laser light, causing the ink-receptive layer to dissolve easily. They are suitable for traditional offset and waterless offset printing, and require post-exposure development, cleaning, and coating.

- Thermal-Crosslinking CTP Plates: These plates undergo a polymer crosslinking reaction triggered by infrared laser exposure, suitable for printing plate-making processes that require precise temperature control. They are ideal for high-quality printing where temperature control is critical.

| Characteristics | Thermal-Melt CTP Plates | Thermal-Crosslinking CTP Plates |

| Composition | 1. Non-roughened aluminum plate | 1. Roughened aluminum plate |

| 2. Ink-receptive layer | 2. Single-layer PS photosensitive layer | |

| 3. PVA layer (for traditional offset) or silicone layer (for waterless offset) | ||

| Imaging Principle | Exposed by a semiconductor laser diode, the ink-receptive layer absorbs energy and becomes easily soluble. | Exposed by infrared laser, the photothermal conversion material converts light energy into heat, triggering the crosslinking reaction. |

| Development Process | The exposed area dissolves in an alkaline solution, forming the non-image areas. | The non-image areas are removed during development, forming the printable image areas. |

| Post-Processing | After development, cleaning and coating are required. | During development, the non-image areas must be removed to ensure clear image areas. |

| Suitable Types | Traditional offset (PVA layer) or waterless offset (silicone layer) | High-quality printing plate-making, precise temperature control |

| Temperature Control Requirements | No special requirements | Temperature must be precisely controlled: too high may cause thermal fog, too low may result in faint image reproduction. |

| Advantages | Suitable for conventional offset or waterless offset, simple processing | Provides high-quality printing results, suitable for high-end printing plate-making. |

| Disadvantages | Requires development, cleaning, and coating, making the process more complex. | Requires strict temperature control, improper temperature may affect the quality of the printing plate. |

Applications of Thermal CTP Plates

Thermal CTP plates are widely used in commercial and newspaper printing industries due to their ability to produce high-quality prints and long print runs. They are suitable for both traditional wet plates and alcohol-based wet plates, ensuring compatibility with various printing machines.

- Newspapers

- Commercial brochures

- Magazines

- Packaging materials

- Catalogs and promotional materials

Due to their high resolution and consistent print quality, thermal CTP plates are essential for any printing application that requires high-quality, long-lasting results.

Thermal CTP plates have revolutionized the printing industry by offering a digital, eco-friendly, and cost-effective alternative to traditional plate-making processes. With their high sensitivity, good water-ink balance, long print runs, and excellent print quality, thermal CTP plates have become the industry standard for high-quality commercial and newspaper printing.

Users viewing this material also viewed the following

Further reading: ctp thermalctp thermal platepositive thermal ctp platethermal ctpthermal ctp machinethermal ctp platethermal ctp systems