What are the three major cylinders used in offset printing?

Apr. 18, 2025

The offset printing process relies on three main cylinders—the plate, blanket, and impression cylinders—to transfer inked images from the printing plate to the substrate.

- The plate cylinder holds the metal printing plate and receives both dampening solution and ink, ensuring only the image areas receive ink.

- The blanket cylinder receives the inked image from the plate and transfers it to the paper, while compensating for slight surface irregularities.

- The impression cylinder applies precise pressure and alignment to press the paper against the blanket cylinder, ensuring high-fidelity image transfer.

Three major cylinders used in offset printing

In offset printing, the three major cylinders play distinct and crucial roles in transferring the image onto the substrate (e.g., paper).

Plate Cylinder

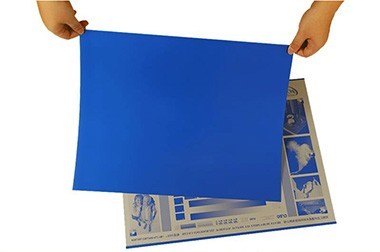

- Function: Holds the printing plate, which carries the image to be printed. The plate is usually made of aluminum and chemically treated to create hydrophilic (water-attracting) non-image areas and hydrophobic (ink-attracting) image areas.

- Process: During printing, the plate cylinder rotates and comes into contact with the dampening rollers (which apply water to non-image areas) and inking rollers (which apply ink to image areas). Ink adheres only to the image areas of the plate.

- Key Detail: The plate does not directly contact the substrate; it transfers the inked image to the blanket cylinder.

Blanket Cylinder

- Function: This cylinder is covered with a rubber blanket that receives the inked image from the plate cylinder and transfers it to the substrate.

- Process: The blanket cylinder rotates around the plate cylinder, picking up ink. Due to its rubber surface, the blanket cylinder can conform to the texture of the substrate, ensuring a sharp transfer.

- Key Detail: The elasticity of the blanket cylinder and the offset nature of the process (indirect printing) enable it to print on various surfaces (such as smooth paper and textured cardboard).

Impression Cylinder

- Function: Applies pressure to the substrate, pressing it against the blanket cylinder to ensure proper ink transfer.

- Process: As the substrate passes between the blanket cylinder and the impression cylinder, the latter's hard, smooth surface (usually steel or chrome-plated) creates the necessary contact for ink adhesion.

- Key Detail: In sheet-fed presses, the impression cylinder may include grippers to hold the substrate; in web presses, it helps guide the continuous roll of paper.

Why these three cylinders?

In both sheet-fed and web offset presses, these cylinders form the core of the printing unit. Large printing systems may include additional cylinders (e.g., transfer cylinders, delivery cylinders, or chill rollers), but they are not part of the main image transfer process. The synergy between the plate cylinder, blanket cylinder, and impression cylinder—through proper water-ink balance, pressure, and registration—ensures precise, high-quality printing.

Synergistic working principle of the three major cylinders

Together, they form the core "cylinder triangle" of offset printing:

- After the plate cylinder absorbs the ink, the image areas transfer the ink to the blanket cylinder.

- The blanket cylinder, with its elastic surface, absorbs and redistributes the ink in a secondary step, ensuring even ink layers.

- The impression cylinder applies pressure, bringing the substrate into contact with the blanket cylinder to complete the final ink transfer.

This synergistic mechanism guarantees the high precision and efficiency of offset printing while preventing direct contact wear between the plate and the substrate.

Users viewing this material also viewed the following

Further reading: offset printing plate making machineoffset printing ctp plateoffset ctpctp offset printing platesctp offset printingctp offset machinectp plates for offset printing