Single-Layer vs. Double-Layer CTP Plates: Pros, Cons, and How to Choose

Dec. 22, 2025

Single-Layer CTP Plate

What Is a Single-Layer CTP Plate

This type of plate has only one photosensitive coating on the aluminum substrate, and both imaging and press run durability rely on this single layer.

A Single-Layer CTP Plate is a commonly used digital plate-making material in modern offset printing. It is defined in contrast to a “double-layer plate,” with the main difference lying in the structural design of the photosensitive / thermosensitive image layer (coating).

Simply put, a single-layer CTP plate is produced by coating only one layer of photosensitive or thermosensitive polymer material onto a properly treated aluminum plate base.

Advantages of Single-Layer CTP Plates:

- Low cost: With a simple structure and mature manufacturing process, the price is generally about 10%–20% lower than that of double-layer plates.

- Fast plate making: The development process is simpler and faster, with relatively lower consumption of developer.

- Good stability: The single-layer structure reduces the risk of interlayer delamination, making it suitable for standard printing environments.

Disadvantages of Single-Layer CTP Plates:

- Lower press run durability: Without baking, the typical run length is usually between 50,000 and 150,000 impressions.

- Weaker chemical resistance: Less resistant to alcohol dampening solutions, UV inks, press washes, and other chemical agents.

- Easy to scratch: The coating is relatively thin and can be easily damaged during transportation or improper handling.

Single-layer CTP plates are currently the most cost-effective mainstream choice on the market. They are ideal for everyday printing tasks such as brochures, newspapers, and standard packaging. If you are using conventional inks, a single-layer plate is fully sufficient. However, if you need to use UV inks (such as for plastic or metal packaging) or if a single job exceeds 200,000 impressions, it is usually advisable to consider a more wear-resistant double-layer CTP plate.

Double-Layer CTP Plate

What Is a Double-Layer CTP Plate

It consists of two coating layers with different functions: the bottom layer provides wear resistance and corrosion protection, while the top layer is responsible for high-precision photosensitive imaging.

A Double-Layer CTP Plate is a high-end plate-making material developed from single-layer plate technology. Its core feature is the application of two layers of photosensitive / thermosensitive materials with different functions on the aluminum substrate, aiming to overcome the limitations of single-layer plates in press run durability and chemical resistance (especially resistance to UV inks).

Advantages of Double-Layer CTP Plates:

- Extremely high press run durability: Even without baking, it can reach 150,000–400,000 impressions or more; after baking, it can exceed one million impressions.

- Full compatibility: Perfectly supports both UV inks and conventional inks. Thanks to the protective bottom layer, it offers excellent resistance to chemical solvents.

- Superior detail reproduction: The double-layer structure enables more precise dot control, resulting in richer image gradation and reduced dot loss during printing.

Disadvantages of Double-Layer CTP Plates:

- Higher cost: The manufacturing process is more complex, resulting in a higher selling price.

- Higher plate-making requirements: Development time is slightly longer than that of single-layer plates, requiring more precise development and processing parameters.

If you are engaged in packaging printing (especially involving UV inks) or ultra-long-run printing, double-layer CTP plates are a more reliable choice and, in the long run, offer better overall cost performance.

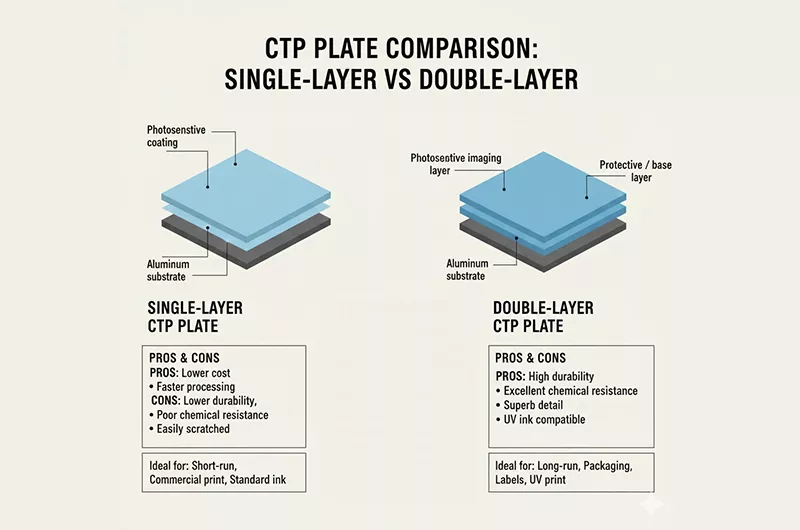

Differences Between Single-Layer and Double-Layer CTP Plates

| Feature | Single-Layer CTP Plate | Double-Layer CTP Plate |

| Structure | Coating + Aluminum Base | Double Coating + Aluminum Base |

| Press Run Durability | Standard (Suitable for short to medium runs) | Higher (Suitable for long-run, high-volume printing) |

| Chemical Resistance | Average | Strong (Better resistance to press washes, UV inks, etc.) |

| Resolution | High | Extremely High (More precise and stable imaging) |

Which Printing Plate Is More Suitable for Your Printing Business?

You can make your choice based on the specific characteristics of your business:

Choose a [Single-Layer CTP Plate] if:

- Business type: Mainly short-run printing and sheet-fed commercial printing (e.g., flyers, business cards, standard brochures).

- Cost sensitivity: Low unit price per job and strict control of consumable costs.

- Conventional inks: Rarely uses UV inks or aggressive chemical cleaning agents.

- Time efficiency: Jobs are updated frequently, with high plate output volume and a strong focus on plate-making speed.

Choose a [Double-Layer CTP Plate] if:

- Business type: Packaging printing, label printing, high-end brochures.

- Long-run printing: Each job requires hundreds of thousands of impressions, and you want to avoid downtime caused by plate wear and mid-run plate replacement.

- UV printing: Uses UV curing technology or UV inks (double-layer plates are the standard choice for UV printing).

- High quality requirements: Customers demand extremely high color accuracy and exceptional clarity for very fine dots.

Users viewing this material also viewed the following

Further reading: ctp platectp machine for printingctp computer to platectp computerctp printingctp plates for offset printingcomputer to plate ctpplate ctpoffset printing ctp plateoffset ctpctp printing platectp offset printing platesctp offset printingthermal ctp plate