Offset Plate Thickness

Apr. 30, 2025

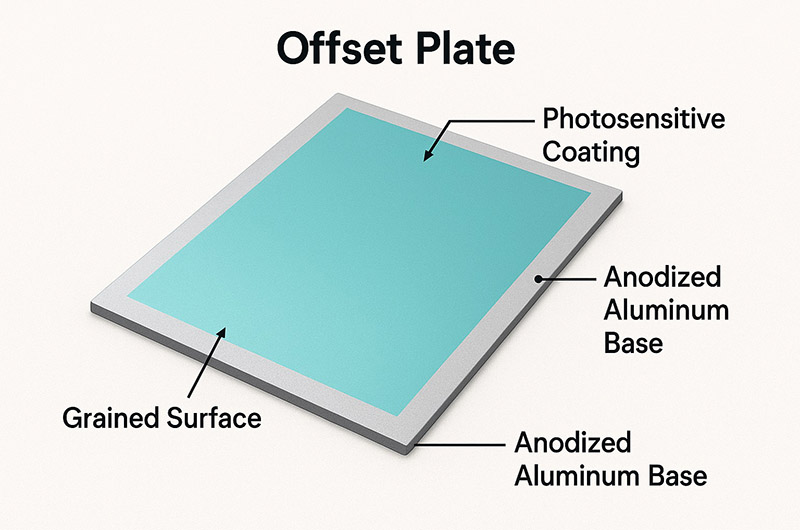

Offset printing relies on printing plates to transfer images onto the substrate. The thickness of the plate is critical to printing performance, durability, and compatibility with printing presses.

Offset printing plates are precision-engineered substrates, primarily made of aluminum, designed to deliver high-fidelity and durable image transfers. Their thickness directly impacts factors such as installation stability, plate lifespan, and ink transfer quality.

Typically, plate thickness ranges from 0.13 mm to 0.30 mm, with special orders reaching up to 0.40 mm. Various manufacturing processes—continuous casting and rolling, belt direct casting, and conventional ingot hot rolling—ensure tight tolerances and optimal surface characteristics, suitable for photochemical or laser imaging processes.

Offset Plate Thickness Range

- Standard Thickness: The most widely used offset printing plate thicknesses are 0.14 mm (commonly specified as 0.15 mm), 0.23 mm (0.25 mm), and 0.27 mm (0.30 mm).

- Substrate Range: The aluminum substrates for PS (pre-sensitized) and CTP (computer-to-plate) plates range from 0.13 mm to 0.30 mm in thickness. In general production, custom thicknesses up to 0.40 mm can be ordered, often subject to minimum quantity requirements.

Surface Roughness

Average Ra: 0.17~0.21μm, ensuring uniform ink adhesion and clear printing definition.

Flatness Requirements

- Side Edge Curvature: <0.2mm

- Diagonal Deviation: <2mm

| Material Type | Thickness Range (mm) | Thickness Range (mil) | Application Description | Structural Features |

| Metal Plate (Aluminum) | 0.15–0.30 | 5.9–11.8 | Most commonly used for high-volume commercial printing. Thicker plates (e.g., 0.30 mm) are used for long-run printing, while thinner plates (0.15–0.20 mm) are suitable for medium-run printing. | Anodized aluminum base, coated with photosensitive layer (such as photopolymer or silver halide) |

| Polyester (Plastic) Plate | 0.10–0.15 | 4–6 | Used for short-run printing (e.g., flyers, posters). Not as durable as metal plates but cost-effective and easy to handle. | Polyester substrate with surface photosensitive coating |

| Paper Plate | 0.3–0.5 | 12–20 | Used for extremely short runs or one-time prints, rarely seen. Low cost but prone to wear. | Compressed cardboard, possibly with a basic coating or finish |

In actual use, plates thicker than 0.30 mm are uncommon and only used when increased rigidity or extended printing cycles are needed.

Why Offset Plate Thickness Matters

Durability: Thicker plates can withstand longer print runs and mechanical stress (e.g., aluminum plates printing over 100,000 impressions).

Press Compatibility:

Printing presses require specific thicknesses to correctly clamp and mount the plate cylinders. Thickness deviations can lead to misalignment or tension issues.

Example: A 0.3 mm plate may not be suitable for a press designed for 0.15 mm plates.

Image Stability: Consistent thickness ensures even contact between the plate, blanket, and substrate, preventing dot gain or loss.

Cost: Thinner plates reduce material costs but also reduce durability.

Offset Plate Thickness Manufacturing Tolerances

- Precision: Thickness must be uniform (±0.005 mm tolerance) to avoid printing defects.

- Thermal/Mechanical Stability: The plate must withstand expansion caused by heat or moisture, which is critical in dampening systems.

Offset Plate Thickness Selection Based on Application

- Commercial Printing: Thick aluminum plates (0.20–0.30 mm) for brochures and product catalogs.

- Newspapers: Thin aluminum plates (0.15 mm) to reduce cost for high-volume, short-run printing.

- Packaging: Durable aluminum plates (0.25–0.30 mm) for printing on abrasive substrates like corrugated cardboard.

- Small-batch Printing: Polyester plates (0.10–0.15 mm) for items like business cards or event flyers.

Aluminum Substrate Grades and Specifications

Offset printing plates use high-purity aluminum alloys (e.g., 1050, 1052, 1060, 1070), typically with aluminum content ≥99.50%, to ensure a uniform surface and mechanical stability.

Series 1 aluminum alloy plates are used, featuring low density, good formability, excellent hydrophilicity, and stable surface treatment—ideal for high-precision printing demands.

After selecting the alloy, the substrate undergoes tempering (usually to H18 hardness) to ensure sufficient strength and flatness during high-speed printing.

Offset Plate Manufacturing Processes

The aluminum base for offset plates undergoes specialized production to achieve the required thickness and surface finish.

Continuous Casting and Rolling

- Molten Metal Casting: Purified aluminum is fed directly between two water-cooled rolls, solidifying into semi-cast ingots 6–8 mm thick.

- Rolling Deformation: The semi-cast ingot is rolled to near-final thickness, forming a fine dendritic structure and dense grain spacing.

- Pros and Cons: This method offers high output and low investment but may suffer from surface segregation and internal quality inconsistencies; mainly used for PS plate substrates.

Direct Belt Casting (Twin-belt Casting)

Melt Spraying: Aluminum melt is poured between two synchronously moving steel belts, rapidly cooled (50–70°C/s), and solidified into thin strips.

Ingot Hot-Rolling

Aluminum Ingot Casting: Aluminum is cast into large ingots and surface milled to remove oxides and inclusions.

Reheating and Rolling: The ingots are reheated above recrystallization temperature, rolled to medium thickness, and then cold rolled to the final thickness.

Microstructure Advantage: Multiple recrystallization cycles improve uniformity and reduce defects, making this the preferred method for high-quality CTP plates.

Online Rolling: Strip is hot-rolled inline, forming a fine-grained microstructure and improving alloy solute retention.

This method achieves excellent flatness and grain refinement, making it ideal for premium CTP substrates.

Physical and Functional Impacts of Offset Plate Thickness

Installation and Compatibility

- Cylinder Fit: Plate thickness must match the specifications of the press (plate cylinder gap), typically calibrated for substrates between 0.15 mm and 0.30 mm.

- Ease of Handling: Thinner plates (<0.20 mm) are more flexible and easier to mount quickly but may bend under high tension; thicker plates (>0.30 mm) provide higher rigidity but increase handling complexity.

Durability and Reproducibility

- Plate Thickness: Plates thicker than 0.25 mm typically withstand longer print runs due to enhanced mechanical support, reducing fatigue over time.

- Dot Fidelity: Precise thickness control ensures consistent coating adhesion (photopolymer layer thickness ~1 micron) and uniform dot reproduction down to 1% tonal value.

Offset Plate Thickness Selection Criteria

When selecting offset plate thickness, consider the following factors:

- Press Type and Speed: High-speed sheet-fed presses generally require stiffer plates (0.23–0.30 mm) for stability.

- Plate Thickness: Thicker plates favor long-run printing by minimizing wear.

- Substrate and Job Complexity: Fine jobs (e.g., packaging) may prioritize surface smoothness over rigidity and prefer 0.13–0.15 mm plates.

- Supply Chain and Cost: Standard thicknesses (0.15 mm, 0.30 mm) are more economical and have shorter lead times; custom thicknesses require additional setup and material costs.

Key Factors Affecting Offset Plate Thickness Selection

Print Volume: High-volume jobs require thicker, more durable plates.

Substrate: Rough materials (e.g., cardboard) need robust plates.

Press Type:

- Sheet-fed Presses: Can handle thicker plates.

- Web-fed (High-speed): Favor thinner plates.

- Cost Constraints: Polyester/paperboard plates reduce costs for small-batch printing.

Though offset plate thickness is a parameter measured in millimeters, it plays a critical role in print quality, press compatibility, and job economics. Understanding the interaction between thickness, substrate alloy, and manufacturing process allows printers to customize plates according to performance needs—balancing print volume, image fidelity, and operational efficiency.

Users viewing this material also viewed the following

Further reading: ctp offset printingctp offset machinectp plates for offset printingctp offset printing platesoffset ctpoffset printing ctp plateoffset printing plate making machine