Does offset printing require plates?

Apr. 11, 2025

Yes, offset printing requires printing plates as a fundamental part of its process. These plates are essential for transferring images or designs onto the final substrate (such as paper, cardboard, or metal).

The reliance on printing plates in offset printing is determined by the nature of the process. Plates are not only the physical carriers of graphic information but also ensure printing efficiency and color consistency through the blanket transfer mechanism, making the method especially suitable for high-volume, high-quality printing needs.

Printing plates are the foundation of the offset printing process. They are the medium used to transfer images onto the substrate, ensuring high-quality and consistent printing results. The choice of plate material and preparation method can significantly affect the efficiency and quality of the printing process.

The Role of Printing Plates in Offset Printing

Offset printing is a planographic printing process that relies on plates to achieve precise image transfer. Each color in the design (for example, the CMYK colors used in full-color printing) requires a separate printing plate. The plate acts as a medium to ensure that ink only affects the intended areas on the printing surface.

Printing Plate Production Process

| Step | Description |

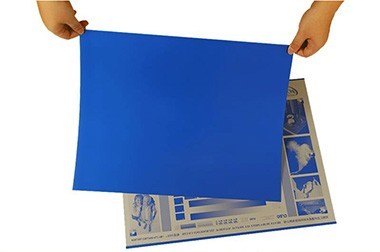

| Material | Plates are typically made from aluminum sheets coated with a photosensitive polymer or chemical emulsion. This material offers good corrosion resistance, dimensional stability, and excellent image reproduction performance. |

| Imaging | Traditional method: A film negative is tightly placed against the plate surface, then exposed to ultraviolet light. The UV light hardens the photosensitive polymer in the image areas, forming the image regions. Computer-to-Plate (CTP): A laser directly etches the digital design onto the plate, eliminating the need for traditional film and increasing precision and efficiency. |

| Developing | After exposure, the plate undergoes chemical development: The non-image areas of the photosensitive layer are washed away by chemical solution, revealing the hydrophilic (water-attracting) aluminum surface; The image areas, having been hardened, remain and become oleophilic (ink-attracting) surfaces. |

Working Principle of Plates in a Printing Press

- Dampening system: Water is applied to the plate and adheres only to the non-image (hydrophilic) areas.

- Inking system: Ink adheres to the image (oleophilic) areas of the plate.

- Offset transfer: The inked image is transferred onto a rubber blanket cylinder, which then presses the image onto the substrate.

- This "offset" step prevents direct contact between the plate and the substrate, thus reducing plate wear.

Types of Printing Plates

- Traditional plates: Require film negatives and chemical processing.

- Process-free plates: Do not require chemical development, using heat or laser ablation to create image areas.

- Hybrid plates: Combine analog and digital workflows for greater flexibility.

Plate Materials

- Metal plates: Typically made of aluminum, these plates are durable and commonly used in offset printing.

- Polyester plates: Lower-cost plates suitable for small-format or medium-quality print jobs, but less dimensionally stable than metal plates.

- Other materials: In certain cases, plates can be made of plastic, rubber, or paper, depending on the specific requirements of the print job.

Necessity of Printing Plates

- Plates are the key medium for distinguishing image and non-image areas in offset printing, directly affecting printing accuracy and color performance.

- Without plates, offset presses cannot complete the ink transfer and printing process.

- Precision: Ensures sharp and consistent reproduction of fine details and colors.

- Durability: Aluminum plates can withstand long print runs (e.g., over 100,000 impressions).

- Cost-effectiveness: Although plate-making adds to initial costs, it is economical for high-volume printing.

Plate Preparation Methods

- Computer-to-Plate (CTP): This modern technology images digital files directly onto metal or polyester plates without the use of film. CTP streamlines the printing process by reducing prepress time, lowering labor costs, and improving print quality.

- Computer-to-Film (CTF): An older method in which digital files are first transferred onto film, which is then used to create the printing plate.

Comparison with Other Printing Methods

- Digital Printing: Does not require plates; outputs directly from electronic files.

- Gravure/Flexographic Printing: Uses intaglio or relief plates, structurally different from offset's planographic plates.

Comparison with Digital Printing

Unlike digital printing (such as laser or inkjet printing), which applies ink directly without the need for a plate, offset printing relies on plates. This makes it ideal for high-quality, large-scale projects, though it is less suitable for short-run printing due to setup time and cost.

Comparison with Gravure/Flexographic Printing

Gravure plates feature recessed image areas that hold ink and transfer it to the substrate under pressure, making them suitable for high-quality packaging printing.

Flexographic plates have raised image areas. Ink is applied to the raised portions and transferred directly to the substrate, commonly used for labels and tickets.

In contrast, offset plates are planographic, meaning the image and non-image areas lie nearly on the same plane. They rely on the physical properties of hydrophilicity and oleophilicity to separate image from non-image areas, making them ideal for high-precision, large-volume color printing.

Key Advantages of Plate-Based Offset Printing

- Superior color accuracy and consistency.

- Ability to print on a variety of materials (textured, coated, or non-paper substrates).

- Lower unit cost for bulk orders.

Printing plates are indispensable in offset printing. They serve as templates for ink application and provide the hallmark precision and scalability of the process. While digital alternatives exist for short runs, plates remain the foundation of high-volume, commercial-quality offset production.

Users viewing this material also viewed the following

Further reading: ctp plates for offset printingctp offset machinectp offset printingctp offset printing platesoffset ctpoffset printing ctp plateoffset printing plate making machine