Computer to Plate Machine Price

Jun. 27, 2025

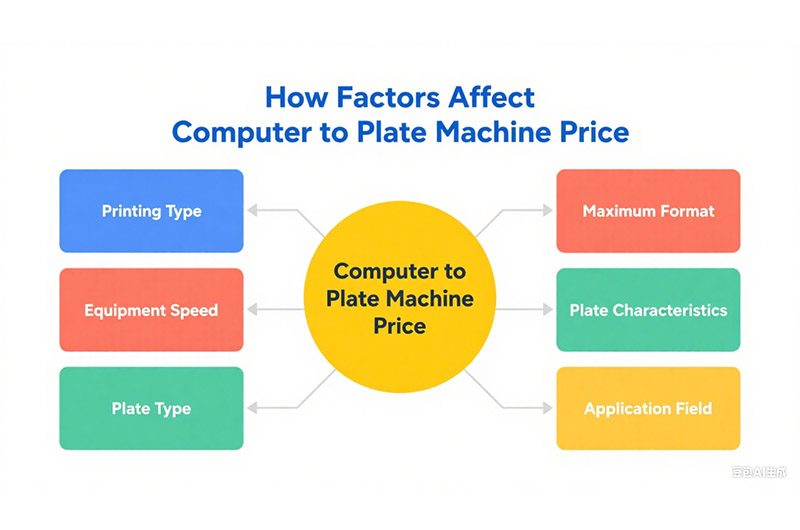

Computer to Plate Machine Price is influenced by multiple factors, including printing type, maximum format, machine speed, plate characteristics, plate type, and application fields. These factors interact in complex ways, collectively determining the final price of the equipment.

- Printing type, maximum format, and application field are the most important factors affecting the Computer to Plate Machine Price.

- Machine speed and plate type come next.

- Plate characteristics have relatively minor influence.

Different combinations of factors give rise to a diverse range of Computer to Plate Machine products to meet the needs of various user groups.

The pricing of CTP machines is a complex process, influenced by a multitude of factors.

Influence of Printing Type on Computer to Plate Machine Price

Different printing processes have distinct technical requirements for CTP machines, directly affecting manufacturing costs and market pricing. The main printing types currently on the market include offset printing, flexographic printing, and gravure printing, each with varying technical demands and price impacts on CTP equipment.

Price Analysis of Offset CTP Machines

Offset printing is currently the most widely used printing technology, dominating the global printing market. Offset CTP machines are mainly categorized into thermal CTP, violet laser CTP, and UV-CTP based on imaging technology, with significant differences in price range:

| Type | CTP Image | Cost Level | Key Features and Application Scenarios |

| Thermal CTP Machine |

|

Highest | High-end positioning. Mainly used in high-end commercial and packaging printing with high requirements. Premium brands show significant price premiums. |

| Violet Laser CTP Machine |

|

Lower | Relatively affordable investment. Ideal choice for cost-sensitive small and medium-sized printing enterprises. |

| UV-CTP Machine |

|

Moderate | Popular for its excellent durability and broad versatility, offering a good price-performance ratio. |

Price Analysis of Flexographic CTP Machines

Flexographic printing, or flexo printing, is widely used in the packaging and labeling sectors, especially in the food and beverage packaging markets. The pricing characteristics of flexographic CTP machines are as follows:

Comparison of Flexo Plate Making Machine Types and Features

| Type | Cost Level | Key Features and Application Scenarios |

| Manual or Semi-Automatic Flexo Plate Making Machine | Lower / Budget-friendly | Entry-level / economical equipment. Low initial investment cost, very suitable for small printing businesses and new users entering the flexo market. |

| Fully Automatic Flexo Plate Making Machine with High Automation | Higher | High-end configuration. Equipment cost is significantly higher, especially for imported machines which carry a substantial premium. Suitable for users pursuing high-efficiency automated production. |

Price Analysis of Gravure CTP Machines

Gravure printing is known for its high quality and long-run printing capabilities, mainly applied in packaging, publishing, and decorative printing. The pricing characteristics of gravure CTP machines are as follows:

Standard Gravure CTP Machines: Generally lower in price compared to high-speed computer-controlled gravure printers.

High-Speed Computer-Controlled Gravure Printers: Very high.

Comparative Price Analysis of CTP Machines for Different Printing Types

| Printing Type | Equipment Type | Cost Investment | Main Application Fields |

| Offset Printing | Thermal CTP | High-Investment Equipment | High-end commercial printing with extremely high-quality requirements and complex packaging printing processes |

| Offset Printing | Violet Laser CTP | Medium-Investment Equipment | Suitable for small and medium-sized printing enterprises with limited budgets |

| Offset Printing | UV-CTP | Medium-High Investment Equipment | Wide coverage, suitable for various conventional printing needs |

| Flexographic Printing | Semi-Automatic CTP | Low-Investment Equipment | Small-scale production scenarios such as small packaging and label printing |

| Flexographic Printing | Fully Automatic CTP | High-Investment Equipment | Meets high-efficiency production demands for large-scale packaging printing |

| Gravure Printing | Standard CTP | High Investment Equipment | Used in high-quality packaging printing and publishing printing fields |

| Gravure Printing | High-Speed CTP | Ultra-High-End Investment Equipment | Applied in high-end packaging and special printing fields with extremely high requirements for production efficiency and quality |

Impact of Maximum Printing Format on Computer to Plate Machine Price

Printing format is one of the important factors influencing the price of CTP machines. CTP machines of different formats vary in mechanical structure, imaging systems, and material usage, and these differences are directly reflected in the equipment pricing.

Common Printing Formats and Their Corresponding CTP Prices

In the printing industry, common printing formats include A3, A2, B1, B2, etc. CTP machine prices differ significantly across formats:

The following is a tabular presentation of the content:

| Printing Format Specification | Suitable Enterprise Type | Equipment Features |

| A3 Format | Small Printing Enterprises | Low cost threshold, suitable for entry-level digital plate making |

| A2 Format | Small to Medium Printing Enterprises | Balanced cost-performance, commonly used in daily production |

| B1 Format | Medium Printing Enterprises, Professional Plate Making Centers | Moderate price, high production capacity |

| B2 Format | — | Considered mid-to-high-end equipment, meets high-precision and high-efficiency production needs, with higher equipment investment |

| Very Large Format (VLF) | Large Commercial and Packaging Printing Enterprises | Extra-large plate-making size, strong production capacity, procurement cost among the highest across all models |

Underlying Reasons Behind the Relationship Between Format and Price

The main reasons why format size affects the price of CTP machines include:

- Increased Material Costs: As the format increases, CTP machines require larger mechanical structures, wider imaging systems, and more powerful power systems.

- Greater Manufacturing Complexity: Large-format CTP machines demand higher manufacturing precision, requiring more sophisticated processing techniques and stricter quality control.

- Increased Technical Challenges: Large-format imaging requires more advanced optical systems and more stable mechanical structures.

- Market Scale Effect: The demand for large-format CTP machines is relatively low, making it difficult to achieve cost advantages from mass production.

Impact of Equipment Speed on Computer to Plate Machine Price

Equipment speed refers to the number of plates a CTP machine can process per hour. It is an important metric for measuring the production efficiency of a CTP machine. Equipment speed directly affects the price—generally, the higher the speed, the higher the price.

Analysis of the Relationship Between Equipment Speed and Price

There is a clear positive correlation between the speed and price of CTP machines. According to market data, the price differences between CTP machines with different speeds are significant:

| Speed Type | Processing Capacity (plates/hour) | Price Range | Main Application Scenarios |

| Low Speed | <10 | Lower price range | Small printing enterprises, low-output-demand scenarios |

| Medium Speed | 10–25 | Medium price range | Medium-sized printing companies, commercial printing fields |

| High Speed | 25–45 | Medium-high price range | Large printing companies, newspaper printing sector |

| Ultra-High Speed | >45 | High price range | Newspaper printing, large-scale commercial printing scenarios |

Cost-Increasing Factors of Speed Improvement

The main reasons why increased equipment speed leads to higher prices include:

- Imaging System Upgrades: High-speed CTP machines require more powerful laser systems and more precise optical components.

- Reinforced Mechanical Structure: High-speed operation demands greater stability and durability from the mechanical system.

- More Complex Control Systems: High-speed CTPs require more complex control systems to ensure imaging accuracy and stability.

- Heat Dissipation and Power Consumption: Higher speeds lead to more heat generation, necessitating more efficient cooling systems.

- Increased Quality Control Costs: Maintaining product quality in a high-speed production environment is more challenging.

Impact of Plate Characteristics on Computer to Plate Machine Price

Plate characteristics—including speed, precision, reliability, and ease of operation—are important factors influencing the price of CTP machines. These features not only affect the performance of the plate itself but also directly impact the design and manufacturing costs of the CTP machine.

Impact of Plate Speed on CTP Price

Plate speed refers to the plate’s response rate to laser exposure, usually measured in millijoules per square centimeter (mJ/cm²). Its influence on CTP machine pricing includes:

- High-speed plates require more precise control systems and advanced electronic components.

- Generally, the faster the plate speed, the more it may compromise imaging precision.

- Different types of plates vary greatly in speed: traditional plates ~2000 mJ/cm², thermal plates ~150 mJ/cm², polymer plates ~0.04 mJ/cm², silver halide plates ~0.03 mJ/cm².

Impact of Plate Precision on CTP Price

Plate precision refers to the smallest dot size and the finest line width a plate can reproduce, typically expressed in lines per inch (lpi) or dots per inch (dpi). Its influence on CTP pricing includes:

- High precision requires more advanced imaging technology, more accurate laser systems, and more stable mechanical structures.

- Increasing precision typically reduces imaging speed or demands more complex technological solutions.

- High-precision CTP machines are usually targeted at high-end markets and come at a higher price.

Impact of Plate Reliability on CTP Price

Plate reliability includes factors such as print durability, stability, and consistency. These influence CTP machine pricing in the following ways:

- Highly reliable plates require better raw materials and more advanced manufacturing processes.

- Ensuring plate reliability requires stricter quality control procedures and more comprehensive testing.

- Reliable plates are often supported by more comprehensive after-sales service systems.

Impact of Plate Operation Convenience on CTP Price

Plate operation convenience includes loading method, plate material compatibility, and user interface friendliness. These affect pricing in the following ways:

- Fully automatic plate loading systems enhance convenience but require more complex mechanical structures and more advanced control systems.

- CTP machines capable of handling various specifications and types of plates need more flexible mechanical designs and smarter control systems.

- A user-friendly interface requires more investment in software development and ergonomic design.

| Plate Feature Combination | Speed | Precision | Reliability | Ease of Operation | Price Range | Main Application Scenarios |

| Economic Type | Low | Low | Medium | Medium | Lower price range | Small-scale printing, low-demand scenarios |

| Medium | Medium | Medium | Medium price range | |||

| High | High | High | Medium-high price range | |||

| Professional Type | Extremely High | Extremely High | Extremely High | Extremely High | High price range | Newspaper printing, high-end packaging, precision printing fields |

Impact of Plate Type on Computer to Plate Machine Price

Plate type is one of the key factors influencing the price of CTP (Computer to Plate) machines. Different types of plates have distinct photosensitive characteristics, imaging principles, and processing requirements, all of which directly affect the design and manufacturing cost of CTP machines.

Relationship Between Thermal CTP Plates and Equipment Price

Thermal CTP plates are currently the most mainstream type in the market. Their relationship with CTP machine pricing is mainly reflected in:

- Thermal CTP machines are relatively expensive and are mainly used in high-end commercial and packaging printing.

- Thermal plates require post-exposure baking under controlled conditions, increasing the complexity and cost of CTP machines.

- Thermal CTP machines offer high stability and excellent imaging quality, maintaining their competitiveness in high-end markets.

Relationship Between Violet Laser CTP Plates and Equipment Price

Violet laser CTP plates are another common type. Their relationship with CTP machine pricing is mainly reflected in:

- Violet laser CTP machines have relatively lower equipment costs and are suitable for small to medium-sized printing companies.

- Violet lasers have a longer lifespan than other CTP laser sources. Due to widespread use in other industries, mass production reduces their cost.

- Violet laser CTP machines can operate under yellow safety lights, providing a brighter darkroom environment for easier operation.

Relationship Between Silver Halide CTP Plates and Equipment Price

Silver halide CTP plates are a high-performance plate type. Their relationship with CTP machine pricing is mainly reflected in:

- Silver halide CTP machines are expensive due to the complex production process of silver halide plates, which require specialized processing equipment and environmental controls.

- These plates contain the precious metal silver, making them more costly. Additionally, silver halide plates must be strictly protected from light, increasing storage and transportation costs.

- The development process for silver halide plates generates toxic waste liquids that can pollute the environment, requiring specialized waste treatment systems.

Relationship Between Process-Free CTP Plates and Equipment Price

Process-free CTP plates are a rapidly developing eco-friendly type. Their relationship with CTP machine pricing is mainly reflected in:

- Currently, process-free CTP machines are relatively expensive due to the complexity of the plate manufacturing process, which requires specialized imaging technology.

- Process-free plates do not require chemical processing, reducing waste emissions and meeting environmental standards. This environmental advantage allows for a price premium.

- With technological advancement and market expansion, the cost of process-free plates and equipment is gradually decreasing.

Impact of Application Fields on Computer to Plate Machine Price

The application field is another key factor affecting the price of CTP machines. Different application areas demand different performance specifications, which are directly reflected in the equipment's design and manufacturing cost.

| Application Field | CTP Equipment Price Level | Key Features |

| Commercial Printing | Medium | Medium speed, medium precision, relatively high reliability |

| Packaging Printing | Slightly High | High precision, high reliability, suitable for complex color and image processing |

| Newspaper Printing | Medium-High | High speed (≥40 plates/hour), medium precision |

| Label Printing | Slightly Low | Small format, medium speed, high precision, high color reproduction requirements |

Further reading: ctp machinectp plate making machinecomputer to plate machinectcp plate making machinectp computer to plate machinectp machine for printingctp offset machinectp plate machineoffset printing plate making machinesmall ctp machinethermal ctp machineviolet ctp machineflexo ctp machine